The Definitive Guide to

In this definitive guide you’ll learn about Supply Chain Visibility, what it is, why real-time visibility is so important, and how visibility can improve your supply chain.

Get the Gartner® Magic Quadrant™ for Real-Time Transportation Visibility Platforms

The report from Gartner is clear – supply chain visibility is critical for every supply chain leader today. Learn how supply chain visibility can help your business.

Supply chain visibility, also known as real-time transportation visibility, or simply real-time visibility, is poised to become one of the most transformative and disruptive technologies in the global supply chain space over the next several years.

Though the technology has existed in some form for decades, the latest generations of visibility tools are finally reaching maturity. And these new tools are rising to the top of industry leaders’ radars.

Whether you’ve never heard of supply chain visibility before, or you’re actively looking for ways to implement it throughout your organization, this page will tell you everything you need to know about this rapidly-maturing software category. Including how it’s being used by some of the biggest players in the global supply chain space.

What is Supply Chain Visibility?

In its simplest form, supply chain visibility collects and presents the real-time location and status of assets throughout the supply chain. This allows logistics professionals to know, in an instant, where their trucks, trailers, ships, and containers are. And, by extension, allows them to keep a closer eye on their assets and make better, faster decisions to optimize their supply chains.

The concept of supply chain visibility has been around for decades, but recent advances in technology and data science have allowed visibility software to become not only useful, but necessary for companies to keep up with global demand.

What kind of tech are we talking? Well, for example, machine learning techniques and artificial intelligence. These technologies have made it possible to use supply chain visibility to not only know where something is at any given time, but to predict exactly when it will arrive at its final destination.

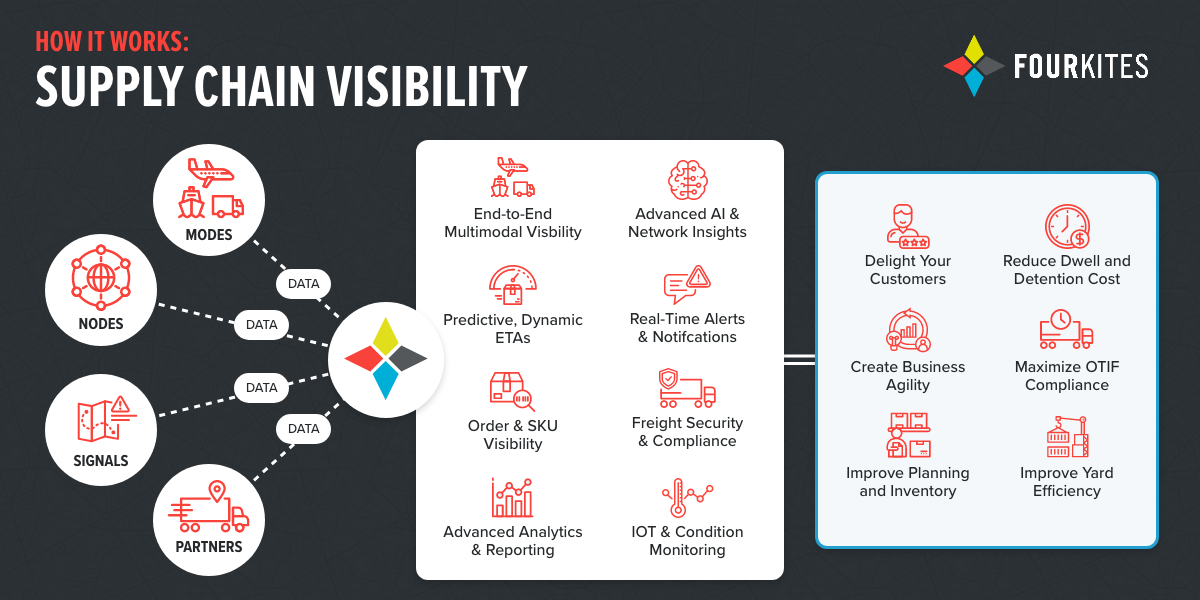

How Supply Chain Visibility Works

It All Starts with Data

Visibility starts with data. It’s hard to make sound decisions if you don’t know where things are in your business, or what their status might be. So the first step to achieving true visibility is pulling together all the data points that are available to you from within your network. These could be onboard telematics from trucks and trailers, temperature and location readings, status updates from ports and terminals, and dozens of other different sources. The data sources will vary according to your industry and business.

Turning Data into Action

Once you have the data, you can start to translate it into actionable insights. For instance, estimated time of arrival (ETA), rates of congestion and delay, and real-time temperature alerts. You can then filter those insights through other data sources. You can filter for inventory levels, production schedules, consumer demand and more. Having access to accurate, real-time information improves your decision-making process in these critical areas of business.

Platforms That Make Visibility Easy

Supply Chain Visibility Software Platforms are software tools designed to make visibility easy. These are platforms specifically built to provide you with easy ways to collect the data you need. And they provide easy to use reports, tracking, and other dashboards specific to your business goals and needs. FourKites real-time transportation visibility platform is one of them.

The FourKites platform leverages patented artificial intelligence to process 150 factors – weather, traffic and real-time data from GPS, ELD telematics networks, mobile devices, AIS and more – to track shipments and provide insights and recommendations based on trillions of data points. The FourKites platform offers 21 out-of-the-box dashboards and reports. Plus automated and customizable notifications that leverage geofencing and temperature tracking. And offers SKU-level visibility to track multimodal shipments — even when they’re split across multiple carriers.

Get Started with a Demo of FourKites >>

Why is Supply Chain Visibility Important?

Visibility Solves Supply Chain Challenges

Disruptions. Amid massive global disruptions and changes to the rules of modern business and supply chain, uncertainty is growing more troubling than ever before. Many companies feel they are operating in the dark, unable to control the many unseen moving pieces of their supply chains, without the required precision or insight.

Customer Expectations. Even with these global disruptions, rising customer expectations remain a constant for many businesses. Customers and consumers alike not only expect to know exactly when their shipments will arrive, but also to be able to keep a close eye on them every step of the way. They demand cheaper shipping and faster delivery, while also requiring more precise ETA’s and a higher degree of control as well.

Supply chain visibility is the tool that help supply chain leaders solve these difficult challenges. Visibility allows them to view their entire supply chain in one single place, to forecast problems and react quickly to them with minimal disruption to their supply chain.

What Are the Benefits and Advantages of Supply Chain Visibility?

There are many business benefits to supply chain visibility. Real-time visibility platforms like FourKites empower companies to have greater control over their supply chain, enabling more effective supply chain management and revealing many opportunities to maximize your ROI.

9 Benefits of Supply Chain Visibility:

- Mitigate supply chain disruptions and manage risk

- Speed up response times

- Improve supply chain efficiency and productivity

- Improve supply chain agility and adaptability

- Gain a precise understanding of supply and demand

- Access to more precise data, insights, and knowledge into your supply chain

- Make smarter, data-backed decisions

- Greater inventory control

- Better customer satisfaction and customer experience

Plus:

Supply Chain Visibility Terms to Know

Supply chan visibility is, by its very nature, a complex subject made up of many abstract and interconnected parts. Because of this, a few critical terms are important to know when researching the impact supply chain visibility technology might have for your organization:

- API

- ELD

- RFID

- Telematics

- RTTVP

API: Application Program Interfaces

API’s are the language of the internet. API’s are how applications talk to each other, exchange information.

ELD: Electronic Logging Devices

ELD’s are GPS-equipped record-keeping devices placed on industrial trucks and trailers to track the location and status of that asset. ELD’s were made mandatory by the U.S. government in December 2017, though they still face a slower rate of adoption in other parts of the world.

RFID: Radio Frequency Identification

RFID is a technique for transmitting digital information about physical objects through the application of scannable tags. Bar codes are one common example of RFIDs, as are the scannable chips in credit cards and passport documents.

Telematics

The raw data from Electronic Logging Devices, RFID’s and other visibility-related devices are collectively referred to as telematics.

RTTVP: Real-Time Transportation Visibility Platforms

RTTVPs are technology tools used by shippers, carriers, and other logistics organizations to gather, analyze and interpret telematics information from a variety of sources, presenting that information in a single, actionable view.

5 Examples of Supply Chain Visibility Solutions

A growing number of shippers and logistics organizations are turning to real-time supply chain visibility tools to help them address inaccuracies and inefficiencies within their operations.

Creating a Digital Supply Chain Model with C&S Wholesale Grocers

One of the United States’ leading grocery supply companies, C&S Wholesale Grocers, rolled out supply chain visibility tools among their workforce with the goal of creating a digital twin for their supply chain. In other words, they wanted to create an accurate, complete digital model of their operation, which would allow them to monitor performance and simulate changes to their logistical practices from anywhere in the world. Using FourKites to track supply chain performance across the company’s 8000+ individual facilities, C&S was able to reduce transportation-related customer service calls by 65% in just four months.

Managing Critical Shipments with 3M

At the start of the COVID-19 pandemic in January 2020, 3M began to drastically ramp up supply chain operations in order to keep up with the skyrocketing demand for N95 masks. In addition to ramping up manufacturing and consolidating their internal processes, 3M added all of their now-critical loads into FourKites, allowing them to control and coordinate the delivery of millions of masks with the ease and agility that had once used to deliver a fraction of that number. Having a scalable real-time supply chain visibility tool, which was capable of handling the added volume, was critical to 3M’s successful efforts to provide personal protective gear to those who needed it.

Eliminating Supply Confusion with Pixelle

One of North America’s top paper and packaging corporations, Pixelle witnessed a rapid reduction in track-and-trace calls after implementing FourKites’ logistics visibility software to provide real-time data across the supply chain. Within less than a year of investing in the new technology, Pixelle’s leadership observed that emails sent by load planners, carriers and customer service groups trying to locate a particular shipment had been cut nearly in half.

Building a Supply Chain Control Tower with Michaels

Michaels consolidated its supply chain management team into a single, centralized control tower, enabling them to empower a small, agile team to quickly and decisively manage operations which once required many times the number of personnel. In doing so, they quickly achieved 91% load tracking, improved on-time delivery, streamlined internal communication and reduced reliance on manual updates.

Supplying Those Who Need it Most with Kraft Heinz

Packaged goods manufacturer Kraft-Heinz uses supply chain visibility solutions to boost performance and improve efficiency over outgoing shipments, bound both for customers like grocery and convenience stores, and also to philanthropic organizations such as food banks. Over the past year or more, Kraft Heinz has used supply chain visibility tools to take a closer look at the efficiency of shipments being dispatched to their partner Feeding America. Ultimately, they were able to optimize their process for getting food to those most in need even as demand for such assistance grew to unprecedented levels in the early days of the COVID-19 pandemic.

Supply Chain Visibility Best Practices

Have a Dedicated Visibility Team

If there’s one thing we’ve seen over and over again as companies embark on their visibility journeys, it’s that having a dedicated team, tasked with driving visibility success throughout the organization, is key. Making visibility deployment part of someone’s objectives and key results is a great way of ensuring that it gets done, and guarantees that there’s someone on deck to follow up with visibility needs internally. Using a visibility provider with a world-class customer success team always helps to ensure speedy implementation and a quick path to positive ROI. Check out FourKites customer success stories.

Choose the Right Visibility Platform

With so many variables, choosing the right tool or platform to enable supply chain visibility can be a daunting task.

Here are some key factors to consider when choosing a visibility platform:

- Carrier Network and onboarding difficulty: Real-time visibility platforms should have a robust operation for onboarding and managing carriers, as well as a strong carrier network both domestically and internationally.

- Integration with Core Business Systems: Visibility is not a replacement for the TMS; rather, the visibility platform you select should offer seamless out-of-the-box integration with your TMS, ERP, etc.

- Multimodal Capabilities: If your business moves freight by a variety of modes (e.g., full truckload, LTL, ocean, rail), then your visibility solution should be able to provide real-time freight tracking across all modes, end-to-end. Don’t try to stitch together offerings from companies with different specialities; one of the most powerful aspects of RTTV is the ability to view your entire supply chain within a single pane of glass.

- Yard-level Visibility: More advanced real-time freight tracking solutions will pair in-transit visibility data with the ability to monitor performance in the yard, giving you increased insight into where delays and bottlenecks are occurring.

- PO-level Tracking: If keeping an eye on individual products is a priority for your organization, you’ll want to go with a solution that can accommodate these requirements, rather than simply sending you blanket updates on the status of a truck or trailer.

- Advanced Analytics: Your platform of choice should provide detailed insights into loads requiring immediate attention, performance of individual lanes and facilities, even the carbon footprint of your entire supply chain.

Automate Your Old Processes

Once you have basic visibility into key metrics throughout your supply chain, you can automate the processes you once had to do manually — like watching out for at-risk shipments. If you know where everything is, and by extension, when it’s most likely to arrive, you can program processes to notify you proactively whenever an at-risk shipment comes along. This allows you to then focus all your attention on fixing the issue at hand, rather than worrying about whether you can find it in the first place.

How to Measure Success With Supply Chain Visibility

Your company will begin to see real, measurable results as you progress further along the visibility journey. The greater your success with real-time visibility, the greater your return on investment will become. These are some of the areas in which real companies have been able to achieve measurable success with supply chain visibility:

- Saving $300K-$500K per month on fines and penalties

- Enabling collaboration to improve capacity by 4% throughout the industry

- Slashing annual penalties by $600,000 per year, or 22% over previous years

- Reducing detention costs by $10 million annually

Get Started with Supply Chain Visibility from FourKites

The road to stronger supply chain management starts with FourKites’ global supply chain visibility software. Contact our team to learn more.