The Ultimate Guide to

What is Ocean Freight?

Ocean freight, also known as sea freight, is the mode of transporting often large and heavy goods by sea. It is one of the most common transportation modes and accounts for more than 80% of all globally traded products. Goods are typically transported in large shipping containers that are loaded onto vessels at ports around the globe. From transporting mass quantities of CPGs to transporting vehicles and electronics, ocean transports play an active and significant role in the supply chain.

Ocean Freight Shipments

How ocean shipping works

The majority of ocean freight is moved in metal shipping containers on a container ship, many of which can carry over 18,000 containers. The two most common container sizes are twenty-foot equivalent units (TEU) and forty-foot equivalent units (FEU). Cargo ships are also used to move items via ocean freight that do not fit in containers, such as large quantities of chemicals and large equipment.

Ocean freight is usually the most cost-effective, but slowest, transportation mode for shipping large product quantities across long distances. Often, large quantities of small shipments are combined into one container to achieve the most affordable shipping rate. Ocean freight is typically the most cost-effective way to transport shipments that are considerable in size and volume, especially those weighing more than 500 kg. While sea freight takes an average of 20-60 days, air freight is a much quicker alternative but can be extremely expensive, especially for heavy items.

International shipments

Ocean freight is often used to transport raw materials or individual parts from Asia to warehouses or factories based in Europe or North America for production, and vice versa. High demand for ocean freight is buoyed by fast sailing times through natural and artificial water routes. Among the most common routes, the ocean freight route from the Yantian port in China to the Port of Los Angeles in the U.S. sees an active flow of ocean liners importing products into the United States with an average transport time of 18-20 days.

Ocean freight deliveries

When a vessel arrives at the port of discharge, it takes a considerable period of time—usually days—to unload the container from the vessel and into the port. These unloading times become challenging when there is port congestion or other delays. Organizations only have a limited number of days available to unload the container before accumulating fees, called Last Free Days. When containers remain on the vessel beyond the Last Free Days, the shipper incurs costly demurrage and detention fees, typically charged per container per day.

Booking Ocean Freight

Global shippers may book ocean cargo directly with the ocean freight carriers or they may work with a third party to book ocean freight, like a freight forwarder or third-party logistics company.

Just three large alliances of the top 25 ocean carriers make up over 90% of global ocean freight volume, including large carriers like Evergreen Line, Hapag-Lloyd, and Maersk. Over recent years, a significant consolidation among the top ocean freight carriers has limited competitive pricing.

Whomever is booking ocean freight faces the challenge of sourcing quotes from the different ocean freight carriers. Ocean rates vary significantly based on the shipping lane (the route the vessel takes), commodity, and season. Typically, organizations need to contact each carrier for a quote. In response, the carrier provides an extensive spreadsheet with hundreds or thousands of rows of rates for lanes, specialized terms, available vessels, and container sizes. This traditional approach is time-consuming, manual, and error-prone.

What are the Challenges with Ocean Freight Booking?

In a recent survey by FourKites, supply chain leaders ranked their top two sea freight challenges as gathering rates and the cumbersome booking process. The same survey found that quotes and booking were automated only 7% and 6% of the time, respectively. Forward-thinking global shippers are beginning to use software solutions to manage the rates and booking processes.

What is the role of a Freight Forwarder?

Some organizations will use a third party known as a freight forwarder to book and manage ocean freight. These freight forwarding companies receive all the shipping information from the organization, including the commodity, lane, and timeframe. Next, the freight forwarders book the ocean freight (or other modes) for the organization—taking over the burden of managing shipment timing and logistics.

The Spiking Cost of Ocean Freight

In addition, ocean cargo rates have spiked dramatically amidst pandemic-triggered supply chain disruption. The cost of shipping a container of goods skyrocketed in recent years, tripling in 2020 alone and continuing to surge according to the Freightos Baltic Index.

These spikes reflect rampant consumer shifts in consumption throughout the Covid-19 pandemic, as consumers reallocate the funds they previously spent on food and entertainment out at restaurants, movie theaters, and bars and clubs—resulting in record-breaking clothing imports, electronics, and furniture purchases. This sharp, unprecedented jolt in shopping habits toppled traditional trade patterns, quickly amassing bottlenecks from manufacturing facilities all the way to consumer doorsteps in the U.S.

Ocean freight is undeniably one of the core tenants of the modern shipping model for supply chain. Still, this transportation mode is dangerously vulnerable to increasing costs and fees, fluctuations in taxes, an excess in mobile data costs, and penalties. The perfect storm of ocean freight fees and other cost variables is an ongoing challenge for supply chain leaders.

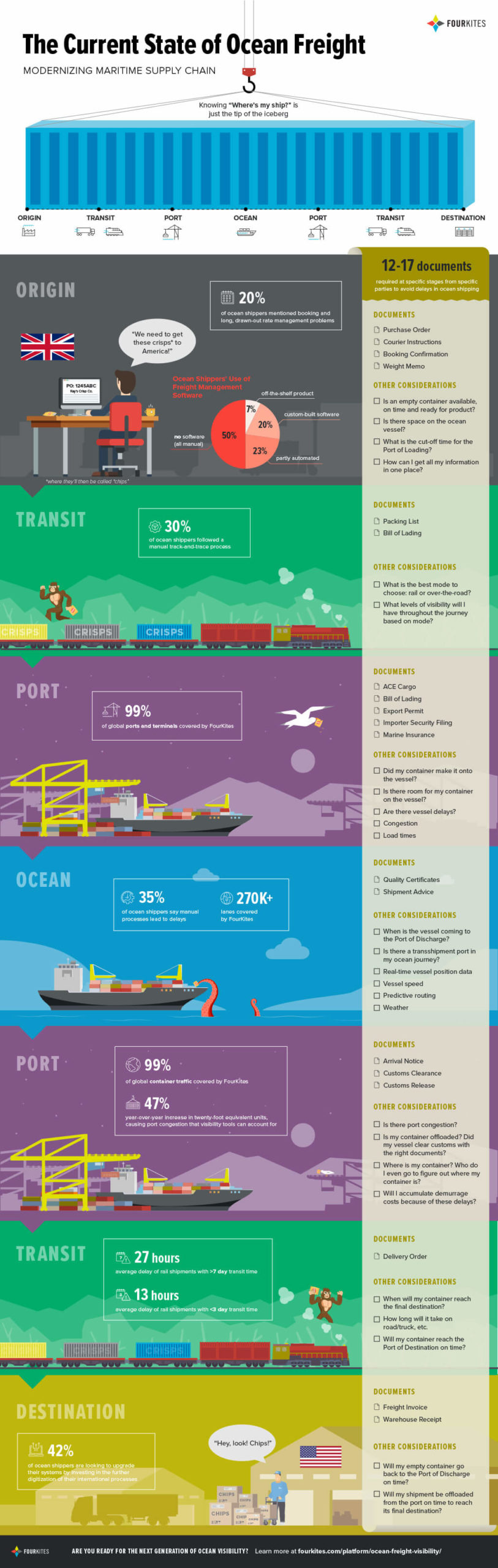

Ocean Freight Document Requirements

On average, an international ocean shipment takes 20 days, requires between 9 and 18 documents, and often requires upwards of 200 emails exchanged between parties to complete. Managing the scheduling and completion of those documents is critical to the successful completion of the shipment. Which documents are required and when is determined by the type of goods you are shipping, the countries of origin and destination, and other factors. Most shipments require a bill of lading, shipping instructions, customs documentation, and letters of credit for suppliers in foreign companies.

Shipping ocean freight internationally includes many requirements from regulatory bodies, national regulations, safety requirements, the customers you are selling to, and the suppliers you are buying from—demanding compliance across every one of them. Organizations shipping internationally need to answer three questions when it comes to ocean freight documents:

- Which documents are required?

- Who is responsible for supplying and approving documents?

- When are documents due?

What are the Major Challenges with International Ocean Freight Documentation?

Incorrect or late documents can prevent your container from being loaded on the vessel and delay your shipment, leading to high demurrage charges and impacting customer satisfaction and profits. For example, the Importer Security Filing (ISF) documentation is due 24 hours before the vessel’s departure. If not completed accurately and filed on time, the container will not be loaded onto the ship.

Two of the major challenges with document management are coordination across parties and detention and demurrage fees.

1. Coordination Across Parties

Shipping documents often require multiple parties to collaborate, review, and approve. These could be coworkers from different departments in a single organization or across multiple organizations, such as freight forwarders, banks and customs brokers.

Many organizations manage this process via email, causing headaches for all. Common challenges are emails getting lost in the Inbox, working on an old version of the document, or being unable to access the document because a collaborator is out of office. It is no surprise that in a recent FourKites survey of senior supply chain leaders, 60% of respondents were seeking options for better document management.

Managing documents in a cloud-based software streamlines operations, improves access and reduces manual errors.

2. Detention & Demurrage Fees Caused by Incorrect Documents

Companies moving a high volume of goods frequently run into obstacles with demurrage and detention charges. These charges are assessed when a shipper uses a container beyond an allotted time frame, often due to delays.

- Demurrage charges are assessed on laden containers inside a port beyond the demurrage free days. In contrast, detention charges come into play after an importer has picked up and unpacked a shipment.

- Detention charges are assessed on containers outside a port. Therefore, the period of detention free days is generally longer than the period of demurrage free days.

This means that even after you’ve moved your cargo out of the port, you need to be prompt in returning the empty containers back to the designated container yard or port, or risk incurring detention fees.

Demurrage and detention fees can cost up to 20 times the price of the container and rack up millions of dollars of unnecessary cost. Ensuring documents are completed accurately and on time can prevent avoidable delays that lead to fees. Learn more about how to reduce demurrage and detention fees.

2021 Report: The State of Ocean Freight Operations

2021 Report: The State of Ocean Freight Operations

Our recent survey discovered significant challenges with managing ocean freight and key areas where automation can create significant ROI for international shippers.

Ocean Freight Visibility

What is ocean freight visibility?

Ocean freight visibility, or cargo visibility, is a specific function of supply chain visibility.

An ocean freight visibility platform uses supply chain data and other factors to deliver actionable insights and reporting. For instance, ocean freight visibility not only provides the precise location of containers and cargo, but also provides more precise ETAs than the estimates typically provided by ocean freight carriers. Ocean freight visibility allows international shippers to track their assets in real-time and identify opportunities to optimize their operations.

Because ocean freight can include multimodal moves as well, many ocean visibility solutions can provide tracking into each leg of the journey or for each mode of the complete container journey. Sophisticated ocean visibility includes visibility into transshipment ports along with a variety of data sources specific to ocean, such as EDI, AIS, terminal data and more.

For ocean freight, visibility is the key to understanding where your container is across long ocean or multimodal journeys.

How has ocean freight visibility evolved?

Gone are the days of track and trace via email, phone and manual processes for your ocean shipments. In the past, international shippers were met with huge gaps tracking their shipments over the seas, unclear where it was located, if it was on schedule or if it made its transshipment port. Additionally, the ETAs provided by the ocean carrier were inaccurate or inconsistent, leading to delays, increased demurrage and detention fines and decreases in customer satisfaction for the shipper.

Now, much like for truckload and over the road shipments, tracking visibility has replaced track and trace for ocean freight. Ocean visibility providers provide the tracking visibility in real-time throughout the ocean journey, including transshipment ports, dray and multimodal legs. Some visibility solutions have evolved from using web scraping to gather milestones and tracking information to using more data sources, such as EDIs, real-time AIS and terminal data.

ETAs have also evolved from the carrier ETAs. Visibility solutions provide predictive ETAs using machine learning technology, incorporating weather, vessel schedules, voyage details, which provide the precise timing and milestones for shippers.

Additionally, the most sophisticated visibility solutions provide insights into the rate and booking process as well as document management. Shippers can better analyze unruly rate cards or secure container bookings, regardless if they use a freight forwarder. These solutions have also evolved to become a digital document hub and collaboration tool to manage required documentation as part of the ocean journey.

How does ocean freight visibility create business value?

According to a FourKites survey of senior supply chain leaders, 50% of survey respondents used a completely manual process for their freight management. This means there is opportunity for organizations to implement visibility to create business value.

What kind of value can businesses expect with an ocean visibility solution? Organizations can expect lower freight costs, increased margins, improved customer satisfaction, improved employee satisfaction and increased optimization.

According to Gartner, “The role of international visibility technology in these uncertain times is more critical than ever before, as organizations face unprecedented challenges to know where their in-transit goods are and when those goods will be available…Supply chain visibility is one of the top cost and governance capabilities to handle events and disruptions.”

In fact, organizations utilizing an ocean visibility solution like Dynamic Ocean have seen 166 hours per month in time savings, 75% reduction in ocean freight booking time, and a 94% improvement in on-time delivery rate. With these savings, the investment in an ocean freight visibility solution would provide a valuable ROI for your organization.

How to Manage Risk in Ocean Freight With End-to-End Visibility

How to Manage Risk in Ocean Freight With End-to-End Visibility

Download this playbook to learn how end-to-end visibility provides reliable, real-time data that empowers shippers to save in freight costs, eliminate surprises, and optimize operations.

What features should you look for in an ocean freight visibility platform?

When evaluating an ocean freight management platform, you should ensure you have the following capabilities:

- True end-to-end visibility across the complete ocean journey

- Visibility into the multimodal legs of the journey and transshipment ports

- Predictive, dynamic ETAs

- A digital document hub for all documents required for your ocean and international freight

- Dashboards and actionable data around accumulating demurrage and detention fines

- Visibility into the rate and booking process, regardless if you book with a freight forwarder or book independently

How to Manage Exceptions with Ocean Visibility

The ocean chaos that international shippers have seen regularly over the last two years is not slowing down anytime soon. Container shortages are still rampant, delays and disruptions are still a key challenge for product availability and astounding demurrage and detention fees are culminating to millions of dollars of transportation fees.

One key challenge amongst all of this ocean disruption is the delays. These could be container delays due to the container shortages; port delays like the debilitating delays at the Port of Long Beach; disruptions at sea such as the Ever Given being stuck at the Suez Canal; or containers missing transshipment ports, blank sailings or rolled containers, where the shipment doesn’t get on a scheduled vessel.

Customers expect these containers and their products to be delivered on-time and in-full and the expectations are even more crucial due to the “Amazon effect”. One way shippers can prevent or reduce the impact of delayed or late containers is through exception management.

What is Exception Management?

In freight logistics, when events such as weather, equipment shortages, or delays at loading cause a shipment to deviate from the transportation plan agreed upon by the shipper, transportation carrier and a customer, it is known as an exception. Exception management is the process of identifying and taking steps to mitigate the impact of changes to a shipment’s intended journey that result from unforeseen circumstances or external forces.

The effectiveness of exception management is commonly measured by its ability to prevent negative outcomes like detention charges, OTIF or missed appointment fines, production delays, and even lost sales and reduced customer loyalty in the retail sector. Specifically in ocean freight management, exceptions can result in containers that are delayed, late or rolled cargo.

The degree to which exception management practices can be successful is highly dependent on the ability to detect exceptions early, while there is still time to take action and get the shipment back on track. Shippers and carriers that have visibility into the entirety of a shipment’s journey are much more likely to be able to adjust transportation plans and mitigate the negative impacts of exceptions. And when end-to-end visibility is paired with artificial intelligence and machine learning, exceptions can be predicted in advance, allowing shippers or carriers to prevent these events before they ever occur.

Benefits of Exception Management

- Lower Transportation Costs

Reduce the added costs from delays, dwell or utilizing alternative modes by prioritizing containers that are late. - Reduction in Demurrage & Detention Fees

Drastically reduce unnecessary demurrage and detention fees through managing delays and disruptions, which can result in millions of dollars in cost savings. - Improved Customer Satisfaction

Keep customers informed on delays and provide accurate ETAs for operations and headcount planning. - Improved Product

Availability Ensure that your shipments make it to store shelves in time and in full for time sensitive promotions, back-to-school or seasonal events even if the containers are hit with delays or disruptions. - Less Spoilage

Prioritize containers that include perishable goods and ensure that they arrive at their destination on time to eliminate risk of inventory loss and increased product and transportation costs.

Learn How To Effectively Manage Exceptions with Ocean Visibility

Download FourKite’s guide to learn the major benefits and best practices to maximize value from ocean exception management.

What are the advantages and disadvantages of ocean freight?

The Advantages of Ocean Freight

Ocean freight is very efficient

Ocean freight is an efficient transportation mode for both shipment size or volume. Containers can accommodate business needs whether you have a small product shipment or a large volume. And it is known for being efficient in terms of pricing for international shipping.

Ocean freight offers more flexibility

Ocean freight also allows supply chain leaders with greater flexibility, enjoying fewer restrictions than other transportation modes. Safety restrictions for transport vary by international and national laws, individual carrier regulations, and carrier organizations regulations. These regulations define and restrict which goods need extra precaution and are considered more dangerous across different transportation modes. Because of these regulations, a whole host of products are not air-cargo compatible. Products that present health risks to the public, are flammable, or include toxic, corrosive, magnetic, or biochemical substances cannot safely ship via air cargo, making ocean freight a reliable alternative for companies across various industries. From beauty products like fragrances and hair sprays; to everyday-use products like cleaners and light bulbs; to consumer electronics like smartphones, ocean freight covers it all. Companies use ocean freight to ship around 60% of all global product shipments via container.

Ocean freight is more sustainable

Ocean freight is more sustainable than air freight. With deepening supply chain transparency fueled by growing regulations and public demand, supply chain sustainability is now front and center. More consumers are willing to find a different brand in a millennial-dominated marketplace if an organization doesn’t produce and distribute products sustainably. Environmental impact is top of mind, and there’s a lot of talk among both business leaders and consumers about reducing carbon footprints. Ocean freight CO2 emissions are a fraction of CO2 emissions for air freight. Air cargo is about 44 times more damaging to the environment in terms of CO2 emissions. For the growing majority of organizations with sustainability targets or values around being environmentally friendly, ocean freight is one of the better modes of transportation with lower emissions than air, truckload, or rail.

The Disadvantages of Ocean Freight

Ocean shipping can take long

Typically, ocean freight shipments take an average of 18-20 days to complete. Ocean freight timeframes are much longer than other modes of shipping freight, including truckload and air freight. The tracking provided by these ocean carriers often occurs at ports, but the ocean journey can be a black hole for that time in between. Additionally, due to longer time frames inherent to ocean freight, correcting issues and completing the shipment can take considerably longer if delays or other problems occur. There are costly implications across the supply chain if there are unavoidable shipment delays—especially when these shipments are not already en route to the final destination.

Ocean freight can be volatile

Wide fluctuations in ocean freight capacity and pricing have also grown more volatile during the pandemic. Not only has there been a shortage of containers in recent years, but there are also limits to the number of containers on each vessel or at ports. Due to these factors and other disruptions driving more frequent shortages, the price for shipping containers and, in turn, the ocean journey has risen significantly. Some organizations have even opted to switch to the more expensive air transport for their shipments.

Ocean freight can require A LOT of resources

Shipping via ocean freight requires staff to spend a lot of time managing rates and booking freight, collaborating on and completing documents and managing carrier relationships – especially when these operations are done manually. Because of this, many shippers choose to work with a freight forwarder or third party logistics providers, which adds a significant amount of additional cost. Forward-thinking shippers are opting to use software that introduces automation into many of these processes, making them more efficient and easier to complete in-house.

What is Dynamic Ocean?

Dynamic Ocean is the next-generation visibility solution that redefines end-to-end management for international ocean shipments. The solution integrates advanced document management capabilities, robust collaboration features and support for bookings, with superior end-to-end real-time tracking. Benefits of Dynamic Ocean include expedited flow of goods through busy ports; significantly reducing detention and demurrage costs; and improved customer satisfaction. Dynamic Ocean covers 98% of global container traffic and more than 750 ports, providing unprecedented visibility into ocean shipments. Comprehensive APIs enable data sharing between Dynamic Ocean and other critical shipper systems including TMS and ERP platforms.

With the FourKites Dynamic Ocean platform, you can go beyond gaining access to the location of your containers with an uninterrupted, real-time view into ocean freight document requirements and ocean shipments booking support rates. Reduce the manual back-and-forth of trace and trace for your ocean containers and gain total visibility into ocean container locations and more accurate projected arrival times. Unleash real end-to-end supply chain visibility for international shipping from booking through destination with FourKites.

Ready to take your ocean freight management to the next level?

Increase agility, ROI, and customer satisfaction while eliminating costly and unnecessary delays, fees, and paperwork errors. Gain deeper visibility and operational efficiency across your ocean freight shipments with FourKites Dynamic Ocean.

2021 Report: The State of Ocean Freight Operations

2021 Report: The State of Ocean Freight Operations How to Manage Risk in Ocean Freight With End-to-End Visibility

How to Manage Risk in Ocean Freight With End-to-End Visibility