What is a Yard Management System?

What Is a Yard Management System (YMS)?

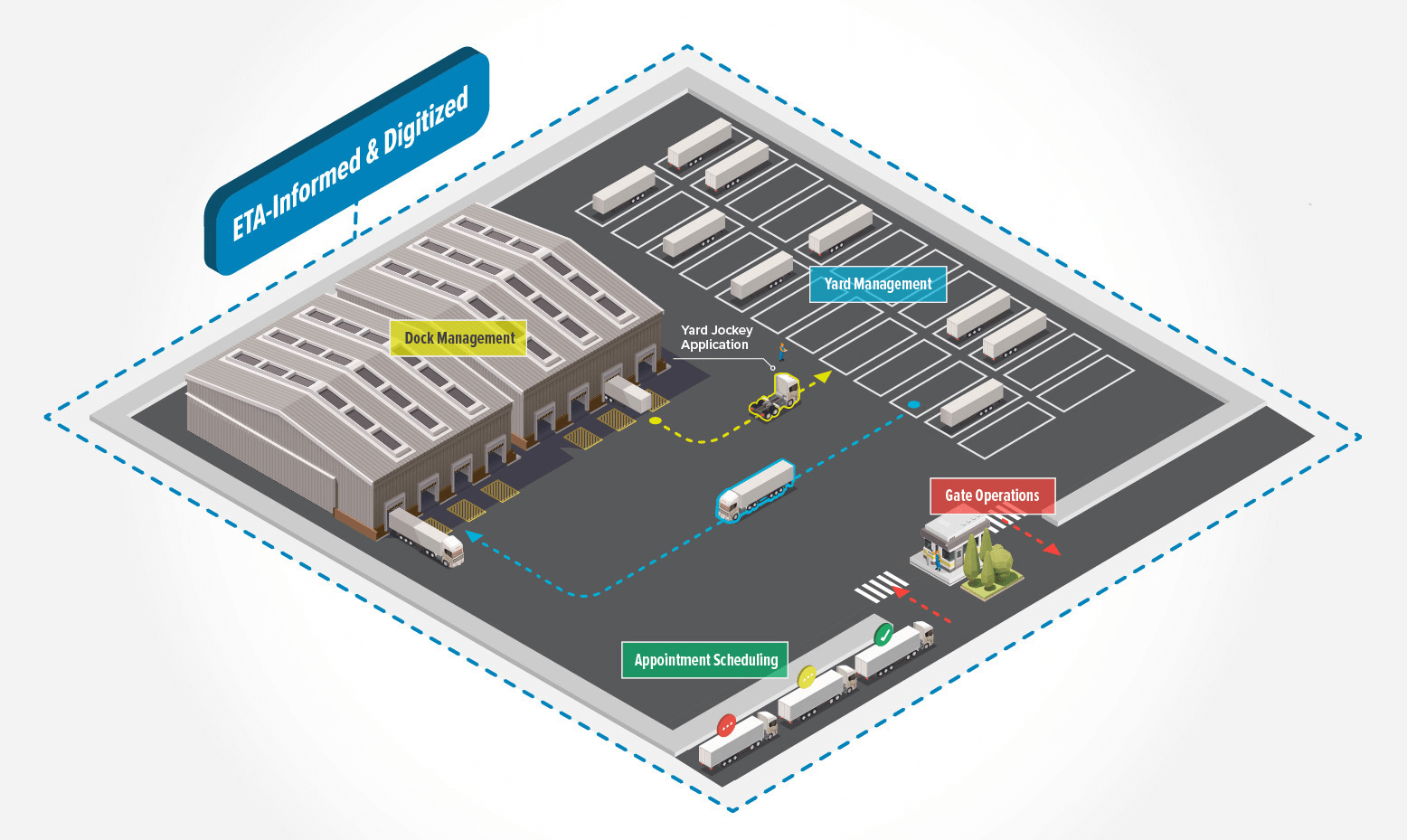

A Yard Management System, or YMS is a software solution designed to monitor the movement of trailers in the yard and dock of a facility, distribution center, or warehouse. Yard Management Systems can create valuable opportunities for agility and efficiency by filling the visibility gaps in your operations between transportation and warehouse.

Transportation → Yard → Warehouse

What is Yard Management?

Yard Management involves the scheduling, coordinating, and directing of assets, such as inbound and outbound trucks, trailers, shipments, personnel, and more, within the dock and yard of a facility.

The challenges of Yard Management continue to grow in complexity and recent supply chain turbulence has led many organizations to look at their yard operations for opportunities to improve efficiency. This is where a Yard Management System comes in, a YMS is a key tool in yard management and optimization.

Today’s Yard Management Challenges

While yard management presents unique challenges for every organization – depending on the size of the company and the yard, products present on the yard and many other factors – here are the key issues we have discovered during our conversations with yard operations associates all over the world.

Challenges At A Glance

- Lack of Trailer Visibility

- Lack of Shipment Visibility

- Process Misalignment

- Yard Jockey Inefficiency

Lack of Trailer Visibility

Yard teams do not have enough insight into available trailer assets in the yard (and possibly inventory), leading to inefficient movement of trailers, increased cost and decreased jockey efficiency.

Lack of Shipment Visibility

Yard teams do not have advanced insight into when trucks will enter the yard for loading or unloading, resulting in inefficient use of the yard and its resources. Additionally, gate congestion and demurrage/detention charges skyrocket.

Process Misalignment

Transportation, warehouse and yard processes are either managed via different yard and dock management systems, companies, or tools that do not dynamically update or are not digitally maintained at all, leading to reactive operations. This means stakeholders do not have insights into what’s happening in real time, leading to inefficient use of warehouse dock doors, labor and equipment, as well as increased costs. Moreover, inefficient use of transportation resources leads to higher wait times, costs and delays, which can negatively impact customer relationships.

Yard Jockey Inefficiency

Lack of insight into yard operations results in inefficient use of yard jockeys and an inability to monitor operations for safety and compliance. This leads to increased violations and charges, as well as wasted jockey labor and poor planning.

The State of Yard Management Solutions: Industry Report 2021

The State of Yard Management Solutions: Industry Report 2021

Download this report to find out how hundreds of Fortune 500 companies are using yard management software to optimize one of the most complex and costly aspects of the modern supply chain: the yard.

Key Benefits of a Dock and Yard Management System (YMS)

When investing in yard management software, it’s important to understand the impact it can have for your organization, and what you should prioritize when searching for the right yard management company and solution. On the importance of an effective YMS, Gartner’s Market Guide for Yard Management had this to say:

Shorter transportation lead times and increasing transportation costs push companies to increase their efficiencies in the yard, as time spent on a yard can be unproductive and costly… Consequently, it becomes even more critical for shippers to find time savings elsewhere in their supply chains. Boosting throughput by using a YMS means trucks spend more minutes with their wheels turning.

– Gartner’s Market Guide for Yard Management

Key Benefits of a YMS

- Yard Asset Management Visibility

- Yard Management Process Flow Improvement

- Cost Reduction

- Carrier Analysis

- Velocity

- Process Conformity

- Continual Process Improvement

- Spotter/Yard Jockey Efficiency

- Carrier Collaboration

- Safety/Security

- Yard of Yards

- Efficient Cross-dock Management

- Yard Appointment and Dock Scheduling Software

Yard Asset Management Visibility

Visibility into yard operations and assets enables effective performance measurement and inventory management. Eliminate time wasted searching for “lost” trailers on the yard. When yard management software integrates with other systems (TMS, WMS, in-transit visibility platform, etc.) organizations have increased line of sight into performance and assets.

Yard Management Process Flow Improvement

Modern dock and yard management systems assist in the automation of traditionally manual processes in the yard, like gate-in, gate-out and appointment scheduling. This leads to increased accuracy of inputs and outputs for better benchmarking. A modern YMS provides shippers and 3PLs with reports and analytics for effective KPI setting and measurement. When performance expectations aren’t satisfactorily met, managers can quickly pinpoint which functions of the supply chain need intervention. With optimized process management, organizations can expect an improvement in the flow of materials through a facility, maximizing utilization of yard and warehouse labor.

Cost Reduction

One of the most important roles of a yard management solution is the reduction of costs across an organization’s yard operations. An effective YMS will lead to a reduction in demurrage and detention expenses by automating and digitizing processes, and managing appointments to ensure smooth carrier operations. Organizations can also expect a reduction in labor costs, as yard workers will waste less time making calls, searching for inventory, completing manual tasks and waiting idly.

Carrier Analysis

For continual improvement, it’s critical to have visibility into the performance of every aspect of the supply chain. By tracking carrier commitments, on-time performance, wait time and unload time, it’s easier to make pivotal decisions about carrier choice and how best to optimize dock labor for speedy loading and unloading.

Velocity

A yard management system provides real-time visibility into asset locations and their operational status, including dwell times in various states. By monitoring all the delays in the visit lifecycle, it becomes possible to streamline operations, for instance by rapidly identifying available empty trailers for outbound loads.

Process Conformity

An effective YMS can ensure that every trailer, tractor and driver entering the facility is checked in and out in a consistent manner. Seals are checked, damage is recorded and shipment information is associated with the trailer number.

Continual Process Improvement

A modern YMS provides shippers and 3PLs with reports and analytics for effective KPI setting and measurement. When performance expectations aren’t satisfactorily met, managers can quickly pinpoint which functions of the supply chain need intervention.

Spotter/Yard Jockey Efficiency

A YMS greatly improves spotter move times and enables shuttle drivers to electronically receive, accept and confirm completion of move requests, eliminating radio communication.

Carrier Collaboration

Top shippers and 3PLs collaborate with their carriers. This collaboration includes providing carriers with access to the YMS, so real-time shipment notifications can be sent.

Safety/Security

A YMS can improve safety by eliminating the need to have people walking around the yard performing manual checks. Instrumentation on yard trucks monitors speed, safe practices and hours of service for yard truck drivers. The YMS also helps secure the yard by tracking all moves from check-in to check-out.

Yard of Yards

Companies with multiple yards do not have access to a single view of all their facilities without a YMS. The network view allows organizations to pool assets, including empty trailers and yard trucks, and to compare operational effectiveness across all locations.

Efficient Cross Dock Scheduling

The combination of YMS with dock scheduling software, warehouse management system (WMS) and workforce management can significantly aid in the ability to efficiently cross dock high volumes of products and materials through facilities.

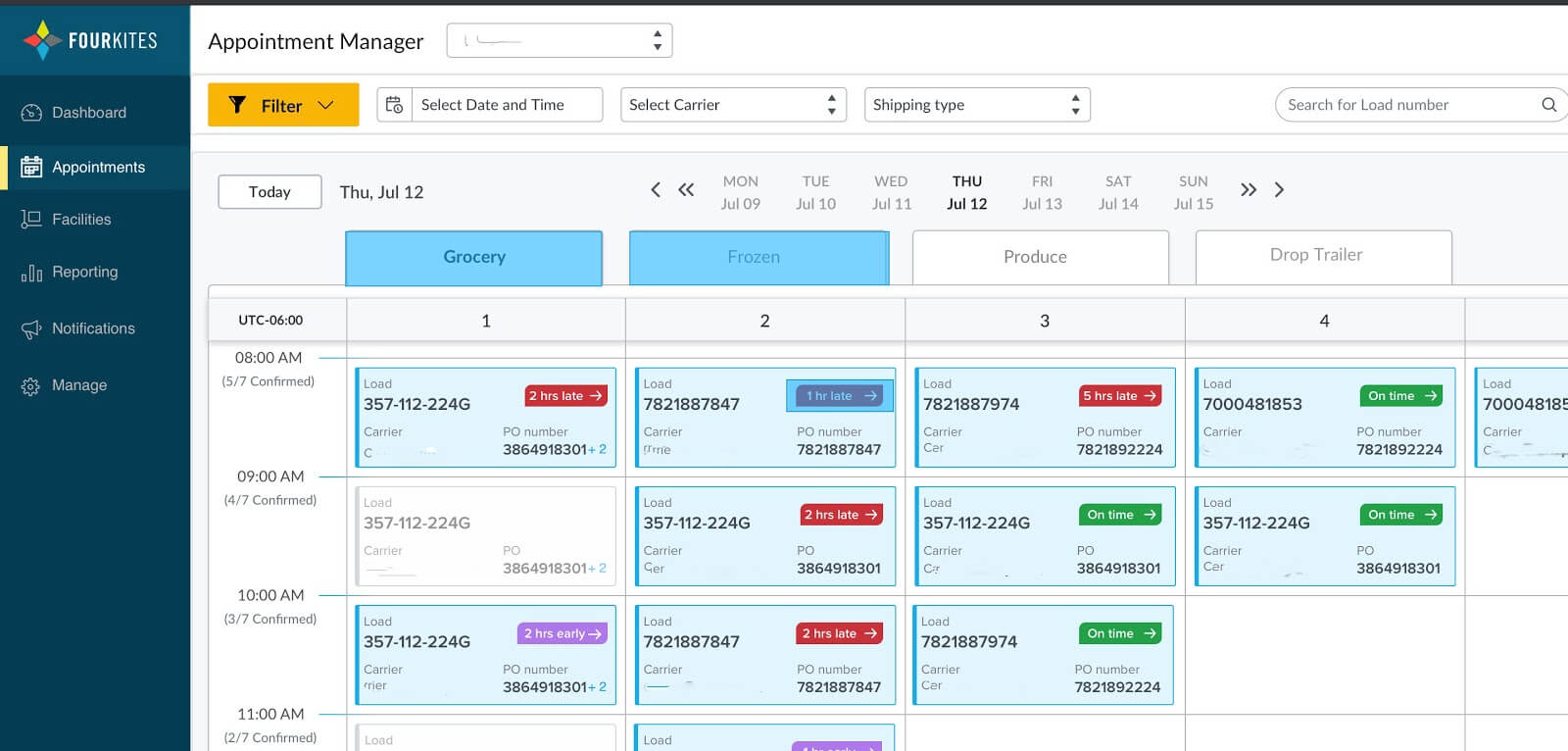

Yard Appointment Scheduling

The next-generation YMS provides shippers and carriers with an integrated appointment scheduling portal to replace time-consuming communication methods, like email and phone calls.

Like all carriers, we feel the acute pain of appointment management every single day. Our dispatchers manage an incredibly complex workflow, which involves managing scheduling and rescheduling across many different platforms… FourKites’ Appointment Manager, which is the first universal platform that integrates with all of our systems, would save our dispatchers approximately eight hours a week, and allow them to shift their focus to higher-value tasks.

– Sanford Gruhn, Director of Sales at K&B Transportation, Inc.

Download the Yard Management: The Last Frontier in Shipment Visibility Infographic

In this infographic, you’ll find unique insights into the state of yard and appointment management across industries, pain points by industry, and areas organizations have identified as opportunities for improvement.

How Has COVID-19 Impacted Yard Management?

Trends in Yard Management Optimization

COVID-19 has presented entirely new and unforeseen challenges across supply chains everywhere. Specifically when it comes to yard management, these roadblocks have shed light on specific areas of weakness, and highlighted opportunities for preventing future breakdowns through automation and digitization. Some of the specific impacts of COVID-19 on yard operations include:

- Companies adjusting their business models and processes to adjust to heightened customer demands and changing consumer behaviors.

- Companies adopting technology by increasing utilization of their existing applications, as well as interest in new applications, such as yard management software.

- Social distancing forcing companies to rethink yard management processes to improve the safety of front-line workers.

Due to the changing landscape of yard management, companies are increasingly relying on yard management services and technology — particularly mobile applications — and shifting their focus to digitization and automation of existing processes. As in-transit freight visibility becomes increasingly effective, shippers and 3PLs have begun to express increased desire for alignment between yard and transportation visibility, along with improved carrier communication and alignment.

Further Reading: Why It’s Time To Adopt a YMS

Maximizing Agility in Dock and Yard Management Systems in the Face of Crisis

How are yard management solutions addressing the challenges arising from COVID-19? We’re seeing increasing adoption of the following technologies:

Better Transit Data

Transportation visibility solutions are able to get better and more predictable data around transit, resulting in more accurate scheduling of shipments and better on-time delivery.

Dynamic Appointment Scheduling

Disruptions in the supply chain have highlighted the need for yard management software to bring about improved accuracy and carrier empowerment via dynamic yard and dock scheduling software. This enables carriers to update appointment windows and alerts them when another stakeholder changes the schedule.

Automation of Gate Processes

For the safety of carriers and frontline supply chain workers, yard management systems have implemented gate process automation. In addition to promoting safety, it also improves accuracy and speed by eliminating the possibility of human error at the gate.

Electronic Documentation

Electronic documentation replaces physical documentation, improving carrier and customer communication and collaboration, and reducing the chance of spreading germs through physical copies. Additionally, this eliminates time spent searching for physical copies of documents, and emailing or faxing them to various stakeholders.

Mobile Technology

Electronic signatures can be collected remotely while safeguarding the driver. The use of electronic proofs of delivery (PODs) provides instant updates, in turn increasing the speed and automation of invoicing.

Emerging Technologies

The use of emerging technologies, such as autonomous vehicles and advanced analytics or AI/ML, optimizes routes and promotes continual improvement.

The ROI of a Yard Management Solution

ROI can come from multiple areas, including reduced detention/demurrage costs through increased visibility to trailer status and dwell times, reduced labor expense with more efficient yard jockeys, reduced infrastructure costs from reduced need for yard vehicles, and more.

For many companies, reduced detention expense has been the largest area of improvement in the yard, with real-time trailer and load status awareness being the biggest drivers of reducing those expenses. While the biggest impacts on ROI can be site-dependent, the average YMS implementation carries the following returns on investment:

- Increased workforce efficiency by 25-30%

- Increased throughput at the dock by 20-40%

- Decreased detention costs by 40-80%

- Total estimated savings per year: $99,752

Total estimated savings calculated based on the following assumptions:

- 2 Spotter Units at $110,000 per year

- Spotters performing manual yard checks for 120 hours at $20 per hour

- Office staff communicating with carriers for 30 hours per month at an hourly rate of $20

- Analysts creating reports for 10 hours per month at a rate of $20 per hour

- Managers performing internal inquiry requests for 10 hours per month at an hourly rate of $20

- Office staff looking up historical moves for 8 hours per month at $20 per hour

- Office staff performing other external inquiries for 8 hours per month at $20 per month

- Average monthly demurrage / detention cost of $4000

ROI estimates provided by Royal4 Systems.

Best Yard and Dock Management Software Companies

Choosing the right yard management solution requires a thorough assessment of the needs and goals of an organization. Your company may need in-depth yard management services, an end-to-end in-transit visibility solution or a less comprehensive solution. Regardless of the outcome of this assessment, a digital solution can help to automate and optimize the yard operations for organizations of any size.

The following breakdown highlights key differences across solution providers:

| Vendor Type | Vendors | Description |

| Application mega-suite vendors | Oracle, SAP | These vendors offer broad portfolios of applications across most application categories (e.g., back-office financials, supply chain management [SCM], logistics, CRM and product life cycle management [PLM]). |

| Supply chain management suite vendors | 4Sight, Aptean, Blue Yonder, BluJay Solutions, HighJump, Inconso, Inform, Manhattan Associates, NCR Retalix, ProAct International, Reply, Softeon, Transporeon, UltraShip, Zebra | These vendors offer a portfolio of applications focused primarily on SCM, including aspects of logistics, but not other functional areas such as financials or human capital management. While these vendors might offer a variety of SCM solutions, not all of them offer an integrated platform. |

| Supply chain visibility vendors | FourKites | These vendors are independent software vendors (ISVs) that focus primarily or exclusively on real-time supply chain visibility, specializing in dock and yard management. Such platforms provide a holistic, end-to-end view of the lifecycle of any given load. |

| Specialist YMS vendors | C3 Solutions, Cypress Inland Corporation, Pinc | These vendors are independent software vendors (ISVs) that focus primarily or exclusively on holistic YMS, although they might offer some additional capabilities. |

Most yard management tools offer minimal appointment, gate and inventory management functionality. The most comprehensive platforms also offer metrics, dock management and carrier tools. Over the next few years, the best YMS software vendors will invest in:

- Capabilities supported by 5G networks

- The use of AI to scan bills of lading (BOLs) and support contactless gate check-in and receiving

- Autonomous, sustainable yard vehicles

- Trailer load optimization technologies through cameras enabled by AI

- Real-time visibility across the supply chain

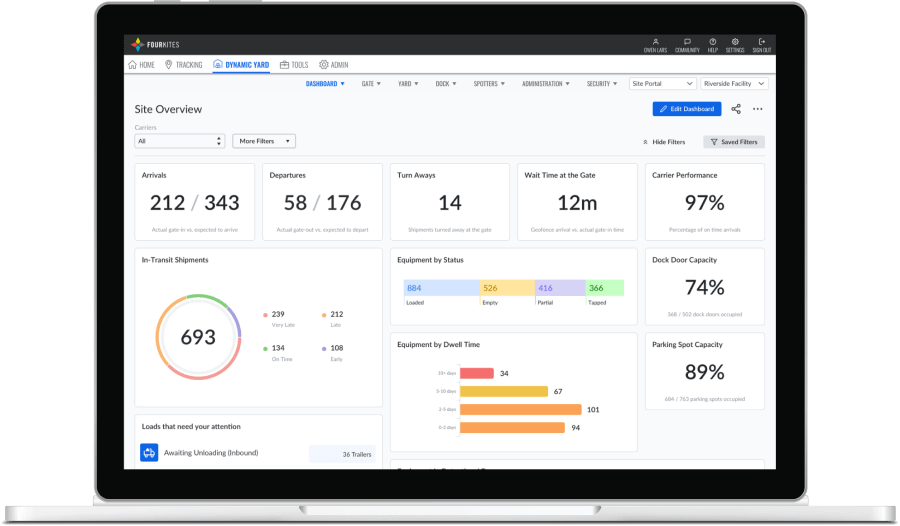

What Is Dynamic Yard?

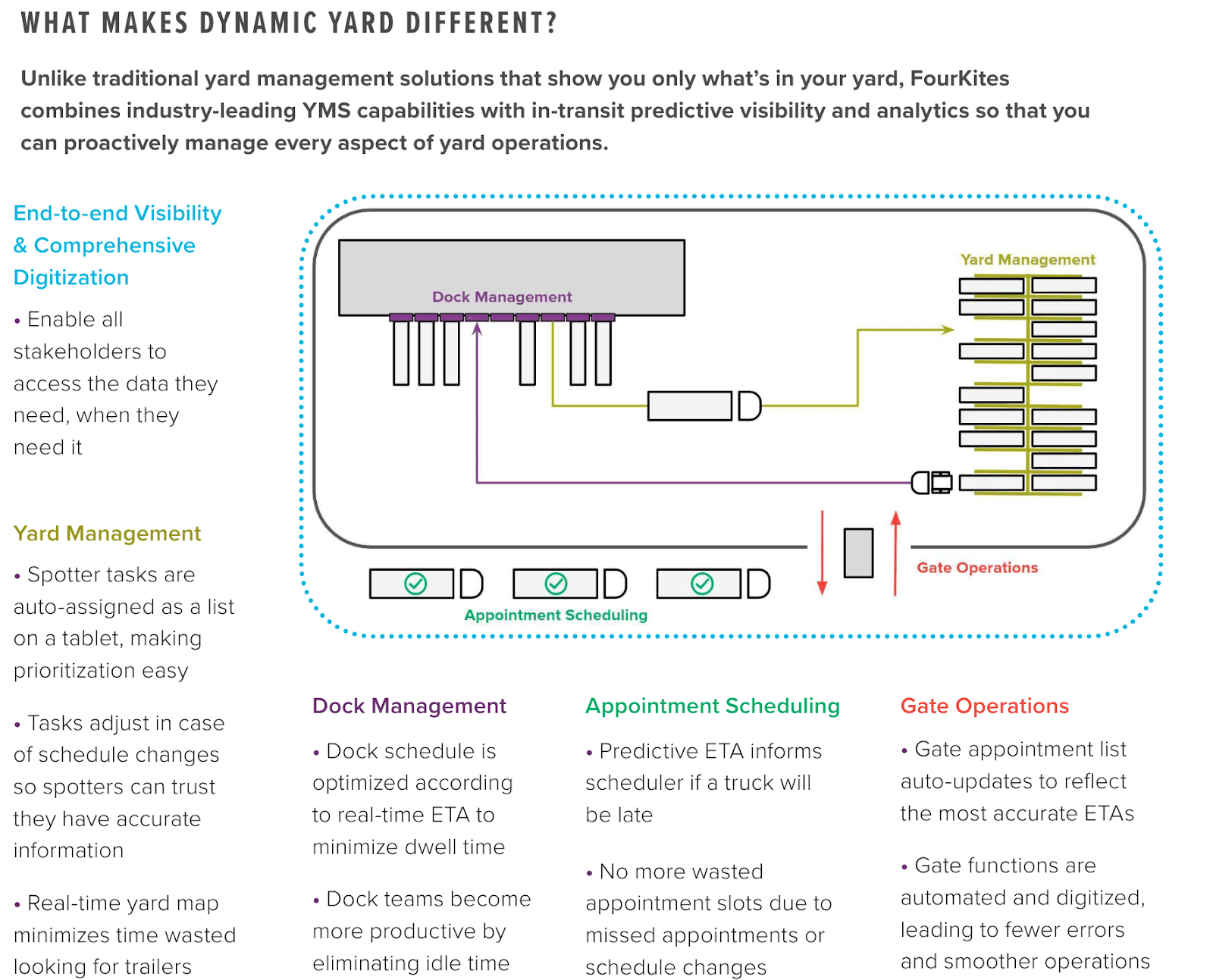

Dynamic Yard is the combination of FourKites’ leading in-transit visibility with yard and dock management software, delivering the logistics industry’s first end-to-end visibility platform.

In the same way that FourKites redefined supply chain management with real-time visibility, it is now bringing real-time in-transit and in-yard visibility to reimagine yard management systems. Unlike traditional dock and yard management software that show you only what’s in the yard, Dynamic Yard combines industry-leading YMS capabilities with in-transit predictive visibility and analytics so that you can proactively manage every aspect of your yard operations.

Yard management solutions have to evolve for the future. We take great pride in the fact that we’ve built this with the input of our supply chain stakeholders, and that, through ongoing conversations with our customers, we’re building the next-generation YMS.

– Priya Rajagopalan, FourKites’ Chief Product Officer

Here’s what sets Dynamic Yard apart from other dock and yard management systems (YMS) on the market.

Scalability

Scalable enterprise solutions for any organization, regardless of size – from the smallest up to multiple enterprise locations. No matter the size and number of sites, Dynamic Yard provides comprehensive reporting and metrics to make sure every site is performing to its potential.

Process Automation

Manual processes keep today’s supply chains from reaching true optimization. Dynamic Yard automates the most basic functions of your yard, freeing up resources to handle higher-value tasks.Spotter task workflow automation and automated alerting and report emails are just a few ways Dynamic Yard streamlines on-site workflows.

Multi-Tenant Visibility

For your supply chain to run smoothly, every stakeholder must be informed of changes happening at every level. Using portals designed specifically for the needs of your carriers and individual sites, your stakeholders are empowered to view changes, manage appointments and complete tasks with ease.

Robust Integrations

By integrating with your TMS, WMS and in-transit load visibility, Dynamic Yard provides the full picture of your operations. With comprehensive data at your fingertips, Dynamic Yard serves as your single source of truth for centralized performance analysis and monitoring.

Easy, Rapid Deployment

With an 8-week standard deployment, FourKites has mastered the balance between deployment speed, meticulousness and time to value. Our team works with you every step of the way to ensure successful deployment.

ETA-Enabled Process Optimization

Visibility into every aspect of your operations enables you to streamline your supply chain. By incorporating real-time, in-transit ETAs into your dock-yard management system, you’ll be able to react quickly to unforeseen obstacles.

FourKites’ Dynamic Yard could become a game-changing solution for us. Our existing YMS is limited when it comes to understanding the real-time status of our freight. FourKites took the opportunity to work with us to understand our need to optimize operations based on tracking and predictive ETA data. Dynamic Yard…could be a real breakthrough that enables cost savings and significant gains in efficiency.

– Belinda Biddle, Customer Experience Manager, Transportation GE Appliances

Still Not Sure if Dynamic Yard® Is the Right Investment?

Still Not Sure if Dynamic Yard® Is the Right Investment?

Check out our playbook to see how to tackle common Yard issues

The State of Yard Management Solutions: Industry Report 2021

The State of Yard Management Solutions: Industry Report 2021

Still Not Sure if Dynamic Yard® Is the Right Investment?

Still Not Sure if Dynamic Yard® Is the Right Investment?