Those of us in international logistics are no strangers to disruptions, but the recent confluence of events — from the Panama Canal drought to the Red Sea attacks and the Francis Scott Key Bridge collapse in Baltimore — is testing the industry’s resilience yet again. As companies scramble to adapt, the ripple effects of these disruptions are being felt across global supply chains. It’s a perfect storm of challenges, and navigating these choppy waters will require flexibility, collaboration, and a healthy dose of grit.

The closure of the Port of Baltimore, a key gateway for automobiles, heavy equipment, and metals, has forced shippers to redirect cargo to other East Coast ports. While analysts like Lee Klaskow of Bloomberg Intelligence believe these ports can absorb the diverted cargo, the shift is not without its challenges — increased drayage distances from ports like New York and Norfolk could add significant costs and strain truck capacity.

According to FourKites data, 92 vessels and more than 2,000 loads had current or upcoming voyages into or out of the Port of Baltimore. As of April 4, 380 loads have been re-routed to the following ports:

On average, diversions and delays are adding 6 days to the estimated time of arrival. However, dwell times at these alternative ports have not been impacted yet.

In the short term, the Tradepoint Atlantic logistics complex offers a lifeline for ro/ro importers and exporters, thanks to its strategic location on the seaward side of the Key Bridge. But let’s be real: this temporary solution does not negate the need for shippers to reconfigure their distribution networks to account for the disruption. It’s a band-aid, not a cure.

Chassis providers, for their part, are confident in their ability to meet the demands of cargo diversions. With utilization rates well below the peaks of 2021 and 2022, companies like CCM believe they have the capacity to minimize disruptions. But the true test will come as cargo volumes continue to shift.

Meanwhile, shippers are grappling with the task of reconnecting Baltimore-bound freight with their established outbound distribution channels. This may involve transloading containers or trailers from alternate ports to distribution centers near Baltimore or further inland. While East Coast ports have the capacity to handle diverted cargo, the availability of truck capacity remains a concern. It’s a tricky balancing act.

As the industry works to mitigate the impact of the Baltimore disruption, it must also contend with the broader challenges posed by the Panama Canal drought and Red Sea attacks. These events underscore the headaches caused by external shocks to global supply chains and the need for those on the front lines to have real-time insight into their logistics network readily available.

FourKites’ AI solution, dubbed Fin AI, detects widespread disruptions and enables users to quickly identify affected shipments. For the Baltimore bridge collapse, we’ve created a “Baltimore-Disruption” tag that flags dray shipments to and from the Port of Baltimore, as well as active over-the-road (OTR) shipments with planned routes on the Francis Scott Key Bridge and alternate routes within the city.

By simply asking, “What events are disrupting my shipments?” users can obtain a comprehensive list of impacted loads within seconds. This streamlined impact assessment allows for swifter action to mitigate potential delays and financial repercussions.

Fin AI also helps customers prioritize their most critical shipments, ensuring that essential products reach their destinations on time. The platform generates instant reports on impacted shipments, delays, and recommended actions, enabling stakeholders to stay informed and aligned throughout the disruption — clear communication is key in these situations.

German pharmaceutical and agricultural conglomerate Bayer has already benefited from FourKites’ AI solution in navigating the Red Sea attacks. Johnny Ivanyi, supply chain senior director at Bayer Crop Science, praised the platform’s real-time insights, stating, “You can see what is the container, what is the roadblock, what is the reason. It’s real time so you can make decisions.” This visibility has helped Bayer better plan production at its manufacturing plants amid shifting shipping decisions. That’s the power of data-driven decision making.

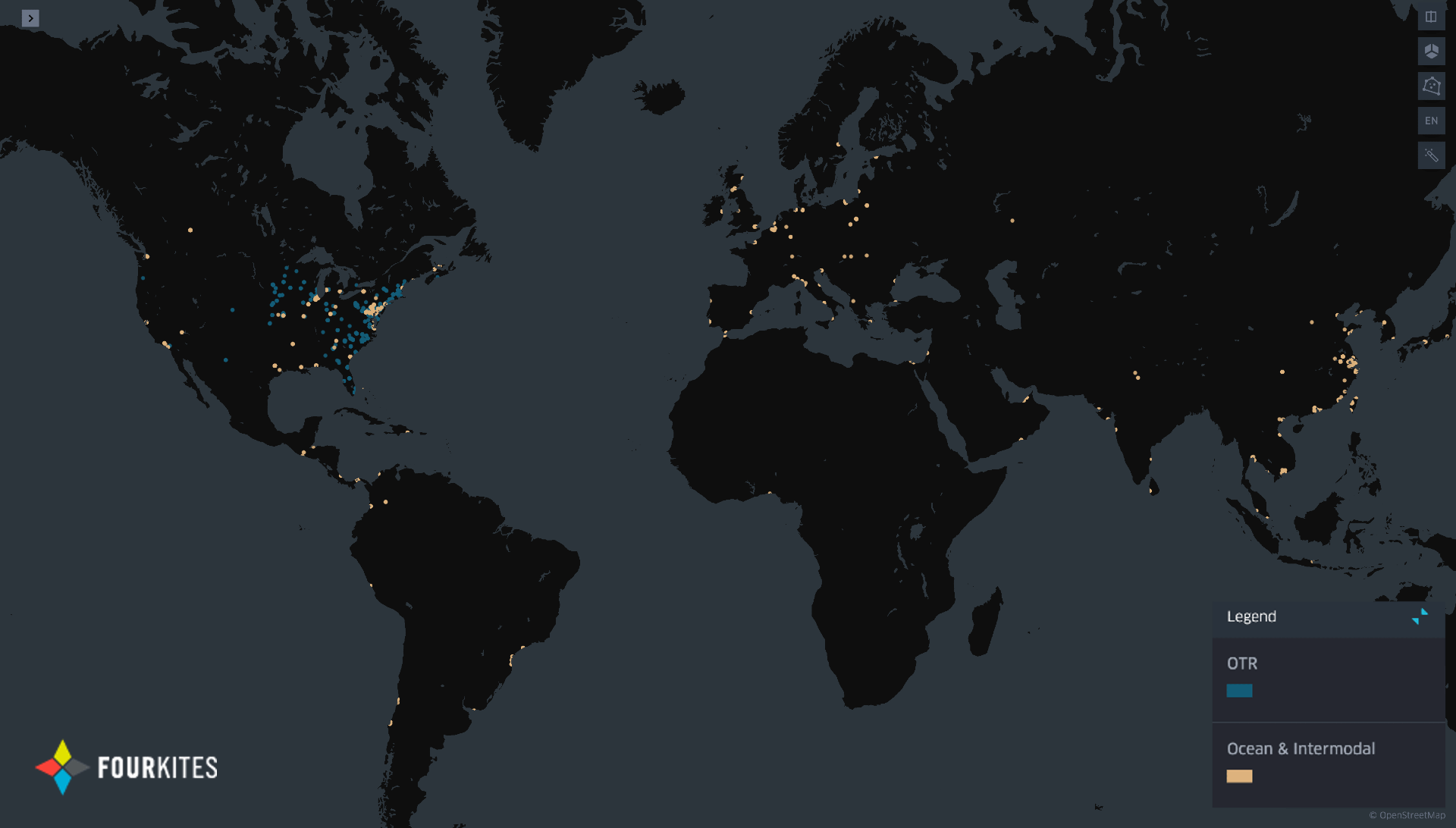

As Fin AI learns from each disruption, it continuously improves its predictions and recommendations for future events, helping customers build greater resilience into their supply chains. With a vast network of high-quality supply chain data encompassing more than 3 million shipments and over 18 million ETAs per day, FourKites is well-positioned to develop highly advanced and accurate AI and ML systems that help customers navigate the ever-changing landscape of global logistics.

Ultimately, the ability of companies to weather these disruptions will depend on their flexibility, adaptability, and willingness to embrace new strategies. As the saying goes, “smooth seas do not make skillful sailors.” The companies that emerge stronger from these challenges will be those that embrace new technologies and collaboration to navigate the choppy waters of global logistics.