We live in an era of technological hype. The journey from groundbreaking innovation to mainstream acceptance is often marked with grand promises, expectations and, sometimes, disappointments. From Google Glass to Theranos, there are countless examples of innovations that were over-promised and under-delivered, were ahead of their time, or were just outright smoke and mirrors.

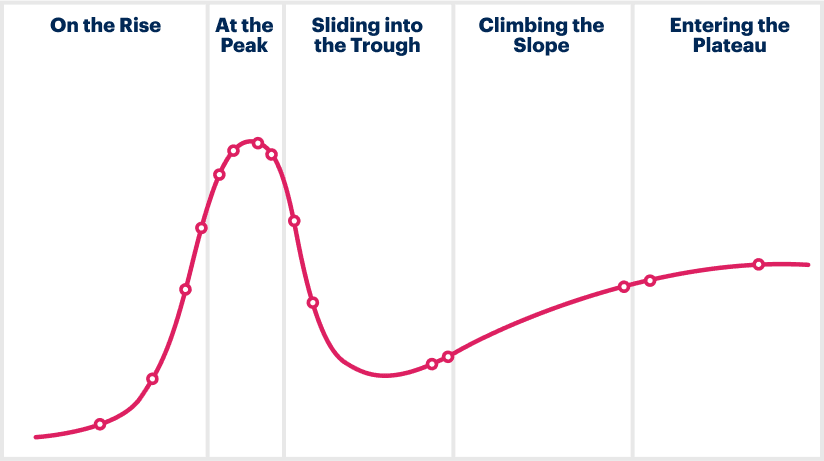

The hype around technology has become such a prevalent issue that Gartner devised a model to understand and anticipate it better: The Hype Cycle. This concept maps out the lifecycle of a technology into five distinct phases:

If you’ve followed Gartner’s Hype Cycle for Supply Chain Execution Technologies, very few technologies — including blockchain, digital twins and delivery drones — have steadily progressed from Phase 1 to Phase 4 or 5.

When reflecting on the successes and failures of these technologies, I have identified several key ingredients necessary for a technology to scale in the supply chain execution space:

Thankfully, as FourKites has grown and matured, we’ve grounded ourselves in these principles by forging partnerships with customers to deeply understand their needs — often co-innovating alongside them. I’m proud that this strategy has paid off, both in our customers’ success and through recognition from Gartner and others as a market leader.

But it’s important that we stay ahead of the curve and don’t fall victim to the hype. To do that, we’re continually rethinking what it means to provide real-time supply chain visibility, and how we can add more value to our customers.

When you look at the real-time supply chain visibility market of several years ago, it was all about solving or addressing foundational use cases: Where’s my shipment? What’s my ETA? What’s the dwell time? Now, not only must a real-time visibility platform deliver on these use cases, but we must help shippers understand the impact of ETAs and dwell times. Smart shippers are no longer looking to simply track their shipments; they’re seeking help with complex use cases, including optimizing labor scheduling, managing safety stock, inventory planning and more.

The fact of the matter is, to solve these complex use cases, you have to integrate with more than just a TMS or an ERP. And you have to build new applications that synthesize supply chain visibility data from multiple sources to help customers with rapid and intelligent decision execution.

More than answering “What’s the ETA?”, FourKites operationalizes supply chain visibility to help frontline teams execute more quickly and accurately. Rather than relying on logistics teams to interpret data and translate it for other core stakeholders, we provide deep, actionable data insights to customer success, inventory, production and procurement teams. By extending visibility to upstream processes, we predict risks and help teams prevent disruptions even before a shipment is created.

Already, we see shippers using these deeper insights to set their strategy. Imagine having the real-time network data and insights needed to:

FourKites empowers teams to quickly evaluate their full scope of options and potential impacts to avoid costly escalations.

This is what we mean when we say “real-time” visibility: the ability to take immediate action the moment minor disruptions occur — not hours later — before they snowball into full-blown problems. And to be truly effective, you must have the complete picture of your supply chain, end-to-end, in real time. That’s why we connect every mode, node and signal through our offerings — from the port terminal to the yard. To be successful, you need to not only see where your shipments are, but also understand the impact of a predicted one-hour delay at the SKU level, inbound or outbound, and be able to act on disruption immediately.

We’ve witnessed firsthand how a deeper level of supply chain insights and recommendations can vastly improve operations, even for those with the most complex logistics networks.

With this vision, we believe real-time visibility is moving beyond hype to help companies build intelligent supply chains for the future.