For many, supply chain visibility is the best first step

If you manufacture high-tech goods like electronics, semiconductors, or computer hardware, your supply chain is likely a tangled web of complexity. With highly outsourced production and distribution networks spanning the globe, achieving true supply chain visibility can feel like an impossible dream. It’s no surprise that 68% of manufacturing supply chain decision-makers don’t believe they have access to the right information and insights to make informed decisions.

But having that clarity into where your products are at every step is becoming table stakes for success. If you can’t provide transparent updates to your customers on their orders, they’ll simply take their business elsewhere to a competitor who can. Robust supply chain visibility is no longer just a nice-to-have but a must-have capability.

In this blog, we’ll explore high-tech manufacturers’ unique supply chain visibility challenges and why lighter-weight, faster time-to-value projects are great stepping stones before initiating other more expensive software options requiring lengthier implementations.

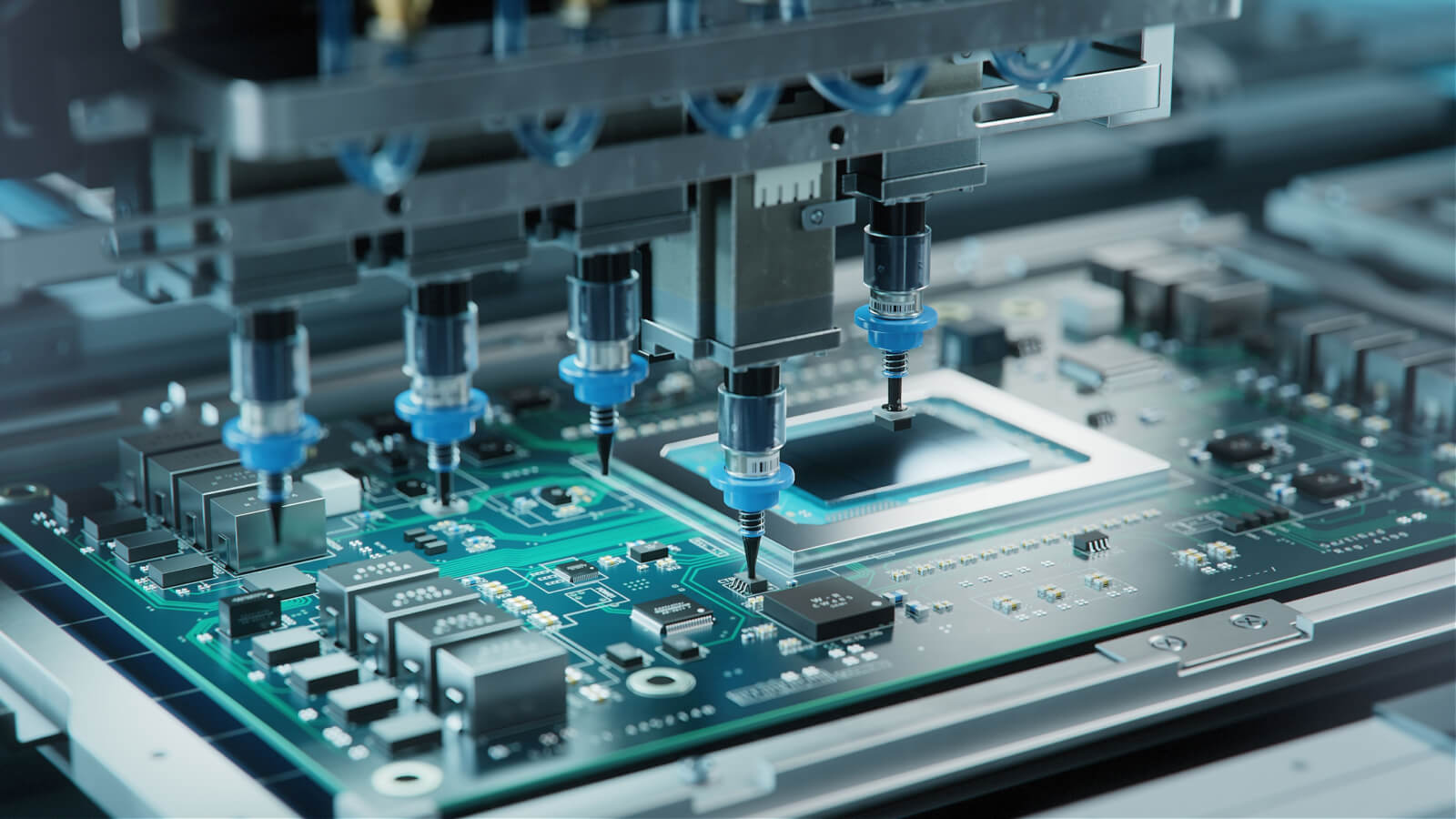

To understand why supply chain visibility is so critical yet so difficult for high-tech manufacturers, you have to appreciate the unique complexity of their supply chain networks. Unlike other manufacturing sectors, high-tech goods are highly innovative and engineering-driven products with massive numbers of components sourced from all over the world — a philosophy that usually bleeds into how they approach their supply chain.

Tracing the path of all commodities like cobalt and rare earth minerals that go into semiconductors is tedious. Ensuring true component-level traceability is enormously challenging with so many intertwined sourcing channels spanning dozens of countries before final assembly.

On top of that sourcing complexity, high-tech manufacturers tend to outsource most of their distribution and logistics networks, giving them little direct control. As one logistics leader at a major chip maker told us, “We don’t control much of the transportation, docking schedules, or freight forwarding — our 3PLs handle all that for us. We’re hyper-focused on product development and speed to market.”

That heavy reliance on third-party logistics providers using their own siloed systems further fragments visibility into the supply chain. If a shipment of processors gets bottlenecked at a port in Malaysia, the manufacturer may not have a clear line of sight into that delay until it’s too late. Seamless cross-system visibility is extremely difficult in a highly outsourced supply chain environment.

Another major challenge is the lack of robust data capture and advanced analytics capabilities across the high-tech supply chain. Most manufacturers only track basic shipment milestone events like departure and arrival times. One supply chain lead at an appliance manufacturer told us, “We’re still heavily focused on lead time analysis by transportation lane versus true end-to-end visibility and optimization.”

However, despite these visibility roadblocks, high-tech companies are perhaps better positioned than any industry to take on the challenge thanks to their cultures of risk-taking and innovation. “Our engineering-driven product mentality means we’re always open to exploring new technologies that can drive competitive advantages for our supply chain,” noted a supply chain executive at an aerospace development manufacturer.

So, with such daunting supply chain complexity, why should real-time visibility be the first logistics capability that high-tech manufacturers prioritize? There are a few key reasons:

1. Investing in a real-time visibility platform is relatively low-cost and low-risk compared to embarking on huge, transformational deployments of technologies like transportation management systems (TMS).

Visibility platforms are SaaS-based cloud solutions versus more serious on-premise TMS deployments. So it’s a much smaller upfront investment to get started, and you can drive ROI quickly with the visibility you unlock.

2. While comprehensive TMS platforms are great for managing core over-the-road freight responsibilities, they have limited capabilities for high-velocity air and parcel shipping, a core part of high-tech supply chains.

Our biggest logistics headache is getting real-time transparency into all the air freight we use to get products spread across Asia into our US distribution channels — a visibility solution is a better option for us to track air freight than a TMS.

3. By starting with a dedicated real-time visibility platform, high-tech manufacturers can get a true end-to-end view into their complex supply chain faster and more cost-effectively than trying to bite off a larger tech overhaul all at once. It allows them to establish that resilient data foundation before layering on more advanced capabilities.

Most high-tech manufacturers don’t start seriously evaluating supply chain visibility platforms until they reach an inflection point of explosive growth that makes their archaic logistics systems burst at the seams.

As a supply chain leader at a fast-growing hardware manufacturing company told us, “We were in crisis mode — growing 30% year-over-year, and our legacy visibility processes just couldn’t keep up. We were missing shipments, letting customers down with constant finger-pointing between our sales, fulfillers, and logistics partners. That’s when we knew we had to do something drastic to regain supply chain visibility before we started losing business.”

Investing in visibility became imperative for other high-tech brands when they expanded into new international manufacturing hubs and markets. One logistics manager focused on TransPac shipping recounted, “We had grown our Asian contract manufacturing channels so quickly that we no longer had a single version of the truth across all those widespread supplier and freight networks. We needed visibility to regain control.”

Sometimes, visibility becomes paramount when a high-tech company prioritizes providing a premium customer experience in a hyper-competitive market. “Our customers just came to expect seamless Amazon-like visibility into their orders as table stakes in our industry,” one components supplier explained. “If we wanted to retain our reputation for innovation and customer obsession, real-time supply chain visibility was the cost of entry.”

Whatever the specific motivating factor, most high-tech logistics professionals find that point-to-point logistics software and manual practices are no longer sufficient once they reach a certain scale and scope of global operations. Investing in real-time visibility becomes an operational necessity.

Achieving true end-to-end supply chain visibility can seem like a dream for high-tech manufacturers weighed down by the complexities of managing ever-challenging global supply chains. But by making smart, manageable visibility investments upfront, these innovative companies can finally gain that elusive transparency and real-time decision-making they need to meet skyrocketing customer expectations and outpace the competition.

While not a panacea for all supply chain woes, establishing real-time visibility capabilities through the right technology platform can be a relatively low-risk, high-reward first step towards resolving issues faster and making smarter inventory and planning decisions.

Want to get started? We’re here to help. Contact us at [email protected].