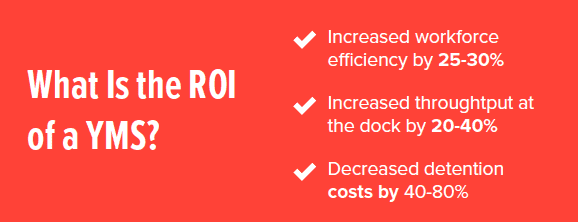

FourKites recently released its fourth and final episode of The Supply Chainiacs’ YMS mini-series. In it, FourKites’ Senior Vice President of Customer Success Glenn Koepke discusses the ROI of yard management solutions, along with some interesting data points from our YMS Industry Report.

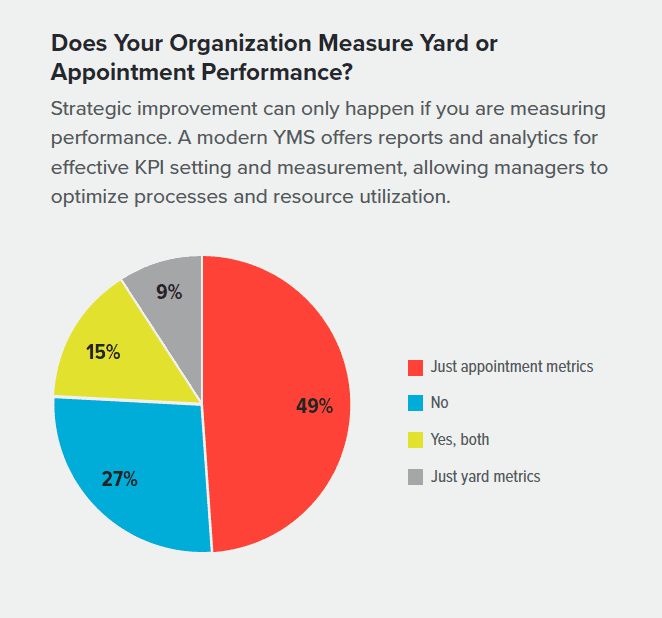

FourKites’ YMS Industry Report surveyed over 300 Fortune 500 companies across all major industries. Findings revealed that 92% of respondents thought a yard management system could or would add value to their organization, but only 21% of respondents currently use a YMS. Carnera hypothesizes that this is likely due to two things: organizations prioritizing other costly areas of the business and a lack of understanding regarding areas of the yard that a YMS can improve. To illuminate these benefits, Carnera walked us through some of the most common cross-yard sources of ROI.

Detention Fees

One of the most common reasons customers come to Carnera for help in the yard is detention fees. Some organizations don’t even know how high their annual detention fees are, but they know it’s too much. With a yard management solution, yard managers can quickly and easily run reports to determine detention spend on a location-by-location basis, as well as organization-wide, cumulative detention spend.

In addition to gaining visibility into detention fees, a YMS helps minimize detention by accelerating in-gating processes through digitization and automation of gate workflows. And with visibility into the contents and locations of trucks on the lot, yard managers can determine which trailers are costing them detention fees, and intervene accordingly to fix the problem.

Labor Costs

Throughout his years implementing yard management systems, Carnera has heard time and time again from yard drivers that it can take them hours to complete a single move because they spend so much time searching for equipment in the yard. With insight into the location of trailers in the yard, organizations can effectively eliminate tedious, time-consuming yard checks — an accomplishment that many customers have been overjoyed to achieve. When a tool assists in expediting time-intensive workflows, it saves organizations money in overtime pay and improves the work/life balance of employees, helping to retain talent and reduce expenses related to employee churn.

Employee Safety

As we all know, yards are constantly busy, with large trucks moving around the yard at all hours and heavy equipment involved in nearly every workflow. This creates an intrinsically risky environment for workers, but a yard management system improves employee safety and reduces costs associated with employee injuries, including medical expenses and replacement hiring/training.

Improved visibility into real-time activities in the yard means employees know what’s happening across the yard and can make informed safety decisions. Additionally, automating dangerous workflows can also help improve worker safety and create an all-around better work environment.

. . . . . . . . . . . . . . . . . . . . .

As we wrap up our Supply Chainiacs YMS mini-series, we want to thank you for following along and point you in the direction of our industry report, The State of Yard Management. It’s chock-full of interesting information and tips and tricks to improve yard operations.

Interested in learning more about Dynamic Yard? Visit our website to learn more about the next generation of yard management systems.