What is the link between trade and the environment, and is it positive, neutral or negative? To answer that question, we need to look at the relationship between trade and transportation, and how much of an impact transportation has on the world around us. As most of you already know, it’s not a very pretty picture.

Transportation globally is still more than 90% reliant on fossil fuels. As a sector, it is responsible for about 25% of energy emissions, and is currently the only sector whose emissions are on the rise rather than decreasing. Part of this has to do with how well other sectors, such as electricity, have moved away from fossil fuels and embraced renewables like wind and solar. Part of it has to do with how consumer buying habits have spiked in recent years due to the pandemic.

Regardless of the reason, however, those numbers are quite disturbing. According to the International Transport Forum, if rail and transport are not decarbonized soon, the global community will not meet the targets set by the Paris Climate Agreement. To that end, I recently had the privilege to join both SAP and the World Trade Organisation to discuss some of the different strategies available to us for achieving greener supply chains before it is too late to save our world.

At long last, sustainability is showing up consistently as a boardroom topic. This is critical because, as we all know, if you want to see anything happening in an organisation of any size, executives must take an interest in it and ask for weekly updates. That’s the way that things start getting done.

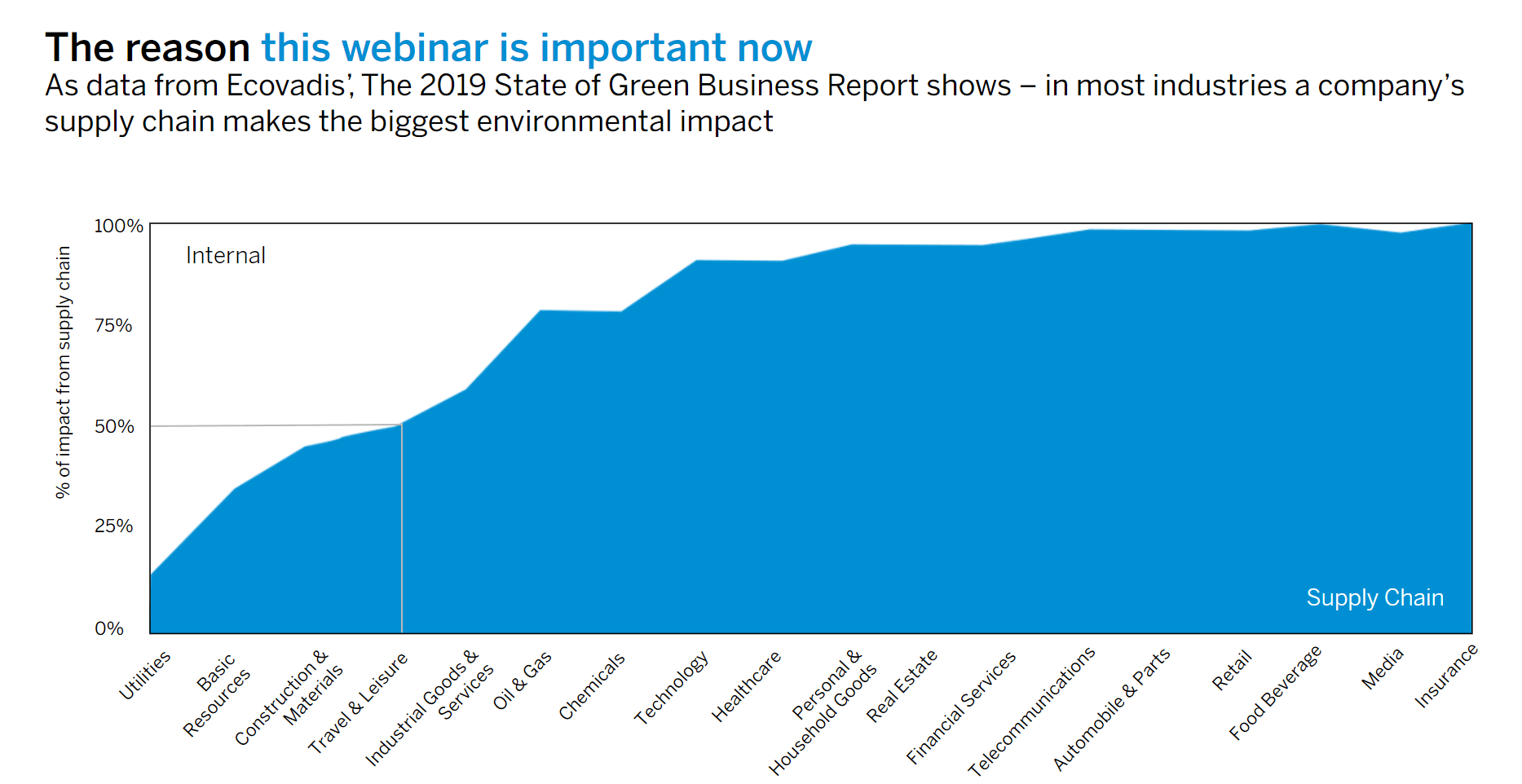

So, if transportation is the largest segment of greenhouse emissions, companies will need to target reducing emissions there first if they want to get serious about sustainability. We’ve seen quite a bit of this happening already, with companies like Amazon and BlackRock taking increasingly strong positions on sustainability. The writing is on the wall at this point that this trend is only going to increase, and now is the time for businesses to start figuring out where their biggest opportunities for sustainability improvements are.

Digitisation is the key, since you can only control what you can see.

Doing so requires investment in technologies that allow you to visualise your supply chain at every level. You need to measure things before you can fix them. You need evidenced-based decision-making on logistics’ contributions to supply chain sustainability. Digitisation allows you to drive your business’ sustainability impacts beyond your own four walls, tracking the performance of suppliers, vendors and other supply chain partners and allowing you to ensure that your partners’ commitments to sustainability align with your own.

Beyond just the company level, sustainability is now a topic of conversation at the highest levels of government as well. I’ve written about this many times in the past, and it’s no less true today than it was back then: Government involvement in sustainability is only going to increase, and businesses need to be ready for it when it does.

It is a growing and consistent trend that governments continue to take more and more measures which are climate-related.

During our discussion, Aik Hoe Lim of the World Trade Organisation identified three major forms that government action tends to take with regard to sustainability:

When it comes to improving your carbon footprint, or any other deeply systemic aspect of your business, the first step is always to develop an intimate understanding of that system and process. Blanket solutions don’t work. For example, even though sourcing a product locally is generally assumed to be more sustainable than importing it, this isn’t always true. Look at the case of a shipment of roses above. Even though it may seem counterintuitive, shipping 12,000 roses to the UK from the European mainland is actually more carbon-intensive than shipping the same number from east Africa – and by a significant margin, as well.

What distinguishes late versus just a long lead time is a lack of visibility. Visibility brings the ability for efficient asset utilisation. This is vital for commercial competitiveness, but it’s also critical for sustainable supply chains, since increased efficiency means fewer shipments.

Whether you buy local or whether you should source internationally depends a lot on the product. It also depends on the production that is required for that product.”

This is the kind of thing you can only learn by having deep, sophisticated visibility into a product’s full lifecycle at all levels of the supply chain. It means investing in traceability technologies that allow you to capture the complete genealogy of a specific product across all tiers of supplier, manufacturer and raw material producer.

Last September, SAP announced the release of its new Carbon Footprint Solution, which helps SAP customers analyse, visualise and ultimately reduce the carbon footprint of individual products across the value chain.

As was mentioned during our recent Supply Chain Sustainability Virtual Summit, it’s critical that businesses who are serious about sustainability find partners who are serious about showing them the way to green their businesses, and to realise that not every company or country is starting from the same point.

“Digital transformation is the only way that we believe people can make sustainability operational in their business,” said Future Planet Founder Donal Daly in a panel moderated by my colleague Rens de Jong. “This is a business transformation. It’s not just about putting a green lens on what you did before. It’s not just about a compliance report.”

If you missed the live event, be sure to check out the videos from the 2022 Global Supply Chain Sustainability Summit available here.