Byte-Sized Delays, Gigabyte Consequences:

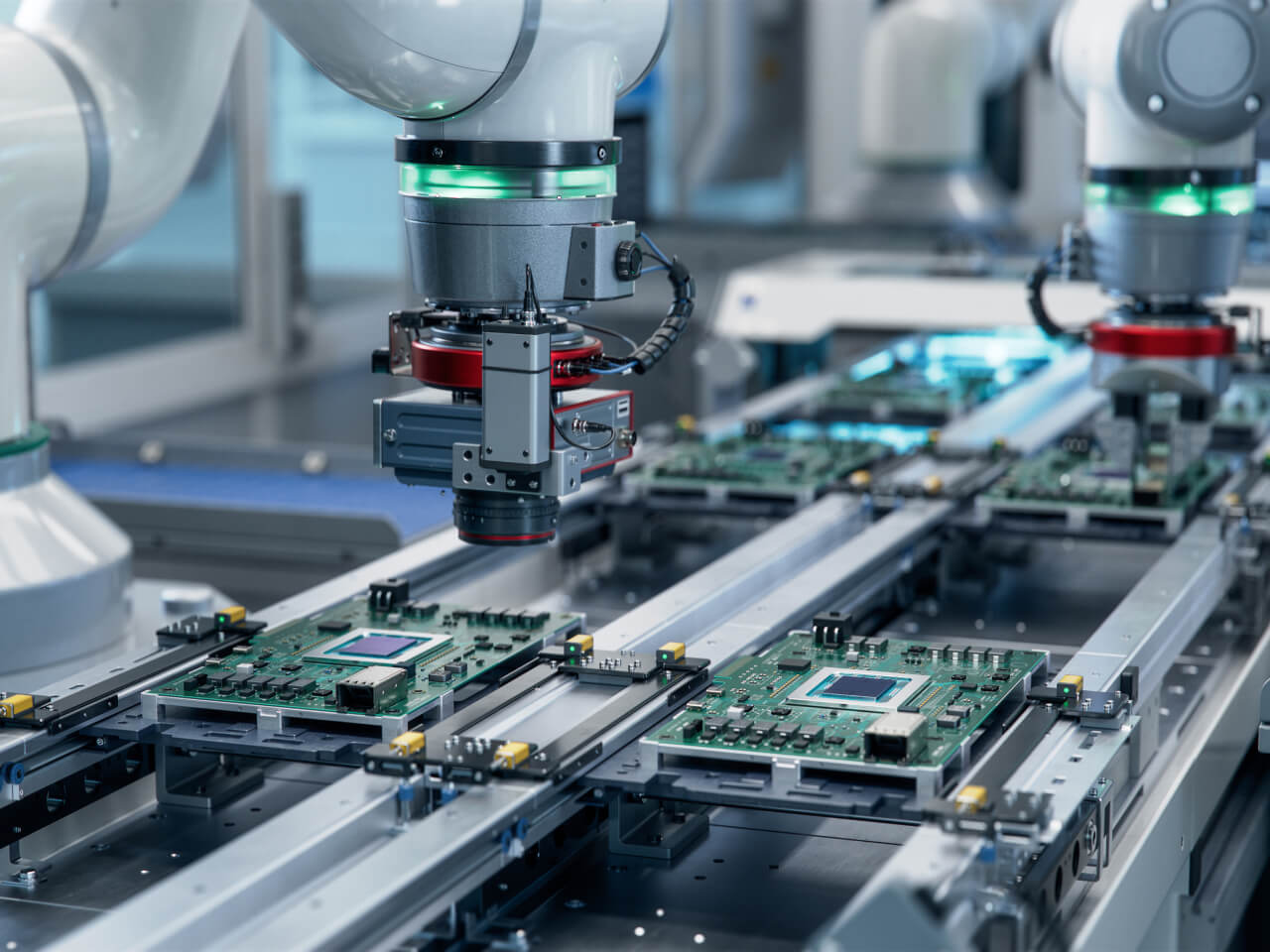

Transforming Western Digital’s Component Command Center

When HDD controller shortages cost millions in missed revenue and impact your ability to meet commitments with key customers like Dell, Meta, Amazon, and Apple, early warning becomes critical. For a company with 85% of its business tied to just four customers, each disruption threatens not just quarterly results but long-term strategic relationships.

The Hidden Cost of Western Digital’s Supply Chain Challenges

With Q2 2025 revenue of $4.29 billion and Cloud segment growth of 119% YoY, Western Digital’s impressive business momentum faces a critical vulnerability: component shortages. These supply chain disruptions are creating significant business impacts:

- Revenue Projection Misses:HDD controller and flash memory shortages directly impact Western Digital’s ability to meet financial targets

- Cloud Growth Threatened: The Cloud segment ($2.3 billion, 55% of total revenue) requires consistent component availability to maintain 119% YoY growth

- Business Separation Risk: Component visibility gaps threaten the successful separation of Western Digital and SanDisk businesses

- Top Customer Relationship Strain: Dell, Meta, Amazon, and Apple (85% of business) face delivery disruptions that erode trust

- Excessive Transportation Costs: 98% of products are shipped by air due to reactive management of inbound delays

- Forecasting Vulnerability: Without visibility into vendor-controlled shipments, Western Digital lacks critical data for the new demand forecasting team

Western Digital’s “Dark Inventory” Problem

Critical components often sit in transit while showing as unavailable in systems. This creates a cascade of unnecessary expedites, manually intensive “Where’s my order?” inquiries, and resource-draining fire drills that prevent focus on strategic initiatives like the CRISP program.

Store Success, Not Stockouts: Western Digital’s Supply Chain Transformation

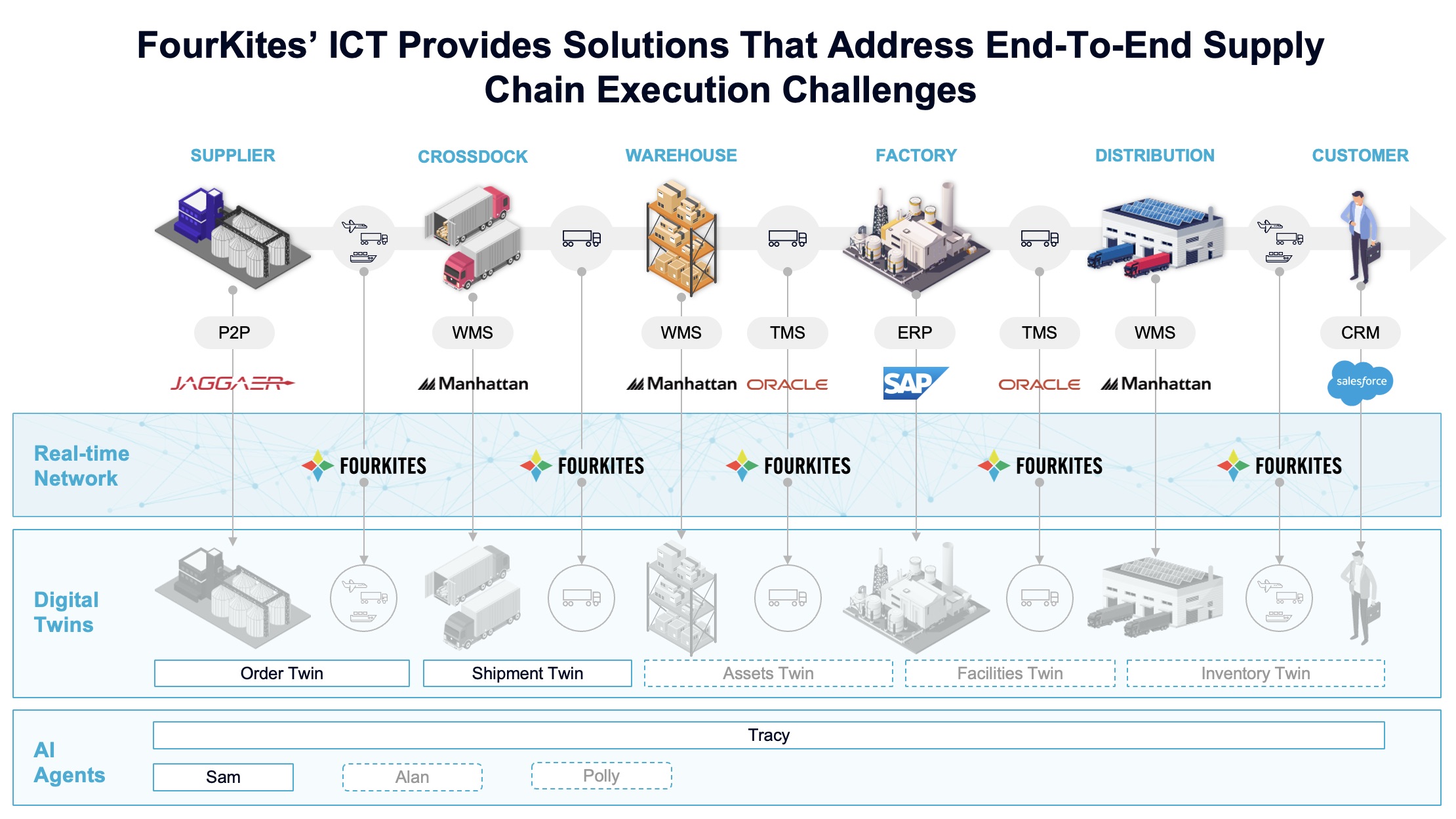

FourKites’ Intelligent Control Tower™ provides Western Digital with true end-to-end visibility, connecting every system and stakeholder across your supply chain:

- Supplier Integration: Close the visibility gap with vendor-controlled shipments

- Digital Twins: Create virtual models of orders, shipments, and inventory for real-time status

- System Connectivity: Integrate seamlessly with your existing P2P, WMS, TMS, ERP and CRM systems

- AI-Powered Action: Automate routine tasks and escalate only critical exceptions

By implementing this comprehensive visibility solution, Western Digital can:

Track Critical Components:

Monitor HDD controllers and flash memory from purchase through production

Predict Delivery Risks:

Identify potential shortages 6-8 weeks before they impact manufacturing

Optimize Transportation:

Support the transition from 98% air freight to more strategic modal mix

Eliminate Manual Coordination:

Reduce time spent on “Where’s my order?” inquiries by 40-60%

Flash Forward: Protect Your Cloud Growth & Top Customer Relationships

According to IDC research, 32% of companies identify upstream supplier collaboration as their most pressing challenge, while email remains the primary communication method despite frequently failing to meet real-time collaboration needs.

This directly impacts Western Digital, where supplier collaboration challenges create:

- Component Stockouts: Delays and miscommunications with suppliers lead to critical shortages

- Customer Confidence Erosion: Disruptions affecting your top 4 customers that represent 85% of revenue

- Excessive Manual Effort: Your team spends hours daily tracking down order status information

- Decision Delays: Critical information trapped in email threads and disconnected systems

By transforming supplier collaboration from email-based to platform-based, Western Digital can prevent the communications failures that lead to component shortages and customer disappointments.

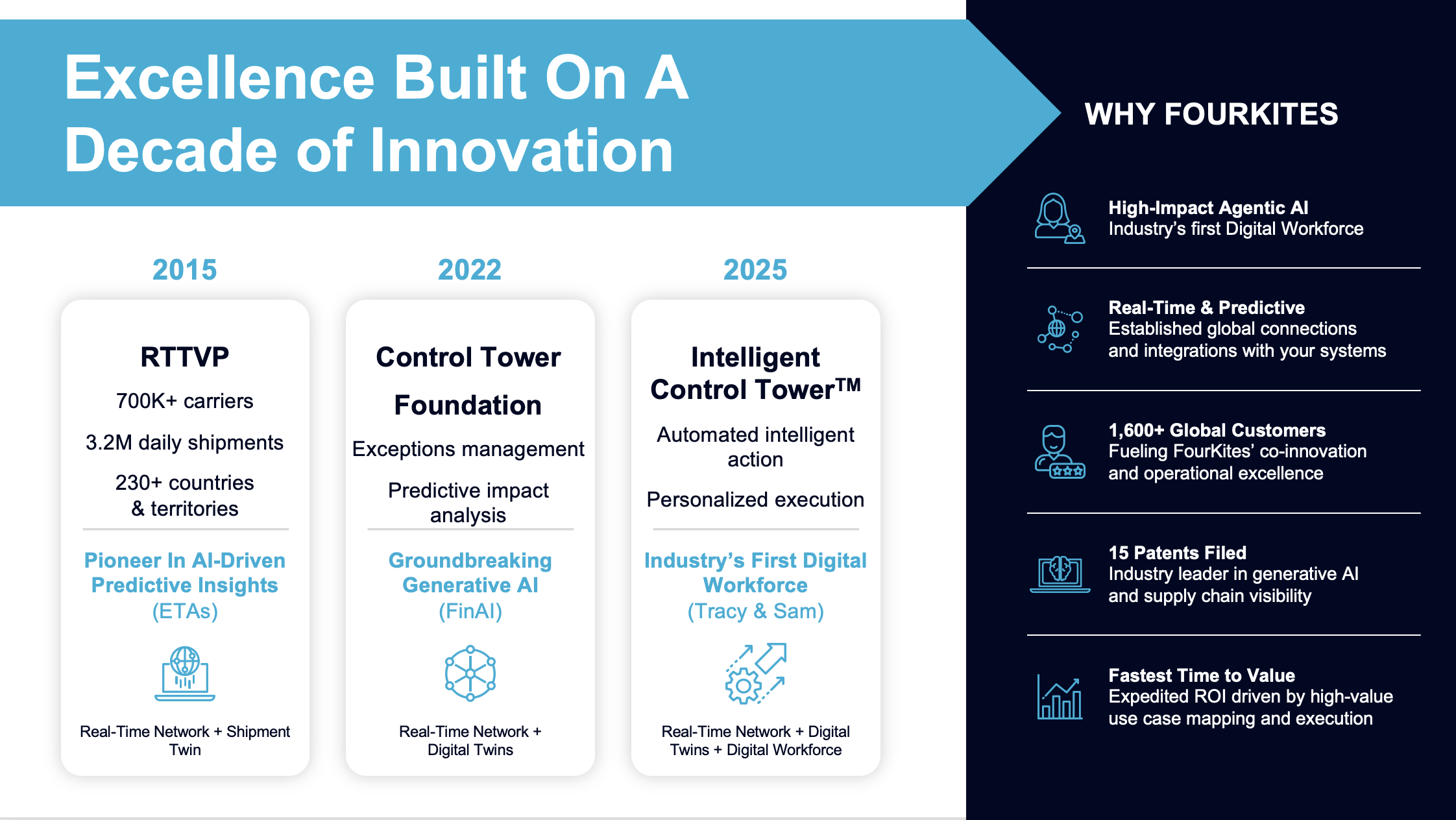

Excellence Built on a Decade of Innovation for Western Digital

FourKites has evolved from pioneering real-time tracking in 2015 to providing Intelligent Control Tower™ solutions with digital workforce capabilities in 2025. For Western Digital, this means:

- Proven Technology: Built on a foundation that tracks 3.2M daily shipments across 230+ countries

- AI-Driven Intelligence: Advanced predictive capabilities developed specifically for complex supply chains

- Digital Workforce Integration: AI assistants that work 24/7 to eliminate manual coordination tasks

- Industry Leadership: Cutting-edge innovation backed by 15 patents in supply chain visibility

This evolution ensures Western Digital receives a solution that addresses today’s component shortages while preparing for tomorrow’s supply chain challenges.

Digital Workforce: AI Automation for Western Digital’s Supply Team

Western Digital’s supply chain team faces constant pressure to locate critical components, respond to status inquiries, and manage exceptions. FourKites’ Digital Workforce transforms this dynamic:

Polly | POD Compliance AI Agent:

Ensures documentation is complete and accurate to prevent delays.

Cassie | Customer Service AI Agent:

Provides proactive updates to Dell, Meta, Amazon and Apple

This AI-Powered Workforce Delivers:

24/7 Coverage: Continuous monitoring of your global supply chain

System Integration: Works across email, ERP, and planning systems

Accuracy Enhancement: Trained on the industry’s largest supply chain dataset

Team Empowerment: Frees your experts from routine tasks to focus on strategic initiatives

Transforming Western Digital’s Key Metrics: Drive Performance, Store Success

By implementing a unified supply chain visibility platform, Western Digital will see measurable improvements in the metrics that matter most:

- Revenue Protection: Prevent component shortages that impact your quarterly results

- Customer Confidence: Deliver 3-5% better on-time performance to Dell, Meta, Amazon, and Apple

- Cost Reduction: Decrease expedited shipments by 15-20% while maintaining service levels

- Team Efficiency: Free your team from “inventory-led fire drills” to focus on strategic initiatives

- Business Separation Support: Maintain visibility through Western Digital and SanDisk transition

Implementation Aligned with Western Digital’s Technical Environment

We understand Western Digital is already investing in visibility solutions:

- OCR Technology Integration: Leverage your existing OCR initiatives for document digitization

- OTM Implementation Support: Enhance your Oracle Transportation Management deployment

- IoT Compatibility: Connect with your CRISP initiative’s smart tables for shipment tracking

- Phased Approach: Begin with your existing data environment while continuously improving quality

Even with data quality concerns, Western Digital can begin improving inbound component visibility today:

See Results Immediately

Begin transforming your supply chain with your existing data environment

Centralized Platform

Ingest and analyze key data feeds from across your tech stack with minimal IT involvement

Automated Data Cleansing

Continuously identify and resolve data inconsistencies across systems

Industry Leaders’ Proven Results

T-Mobile Success Story

T-Mobile faced challenges similar to Western Digital with siloed systems and inaccurate arrival times affecting planning.

The Results:

- Eliminated 1-2 days of wasted inventory time

- Reduced manual communication between teams

- Enhanced product delivery to customers

Best Buy Transformation

Best Buy struggled with reliance on external partners for critical data and lacked the crucial visibility of “what’s in transit, what’s happening right now.”

The Results:

- Saved approximately $10 million annually through more dynamic routing

- Eliminated siloed knowledge and created standardized analytics

- Improved carrier accountability with real-time data

Customer Quotes

"FourKites really stepped in and filled that 'what's in transit, what's happening right now' gap. We've been able to create more dynamic routing, wherein we're using our real-time orders to adjust the route planning of certain loads, which we've saved about 10 million a year."

“In the past, our market personnel had to wait for a notification that the material had arrived, then they would schedule a pickup, potentially waiting a day or two. With visibility, the market personnel know exactly when they need to arrive, which reduces unnecessary wait time and it has actually reduced the amount of time it takes for us to get material into the hands of our end users.”

Supporting Western Digital’s Strategic Priorities

Power Your AI Data Cycle Strategy & Business Separation

- Support the 119% YoY growth in your Cloud segment by ensuring component availability for high-capacity enterprise drives

- Optimize flash component inventory through real-time visibility into your joint venture with Kioxia

- Maintain component visibility through Western Digital and SanDisk separation with distinct inventory strategies for each business

Prevent Component Shortages & Optimize Transportation

- Track thousands of vendor-controlled component orders throughout their entire lifecycle

- Create a single source of truth for inventory in transit, in yards, and in warehouses

- Shift from 98% air freight to a strategic modal mix through improved planning

- Support your hiring of demand forecasting personnel with predictive analytics

Enhance Top Customer Experience

- Eliminate “Where’s my order?” inquiries from Dell, Meta, Amazon, and Apple

- Provide accurate predictive ETAs based on actual transportation and inventory data

- Build customer confidence with consistent, reliable component availability