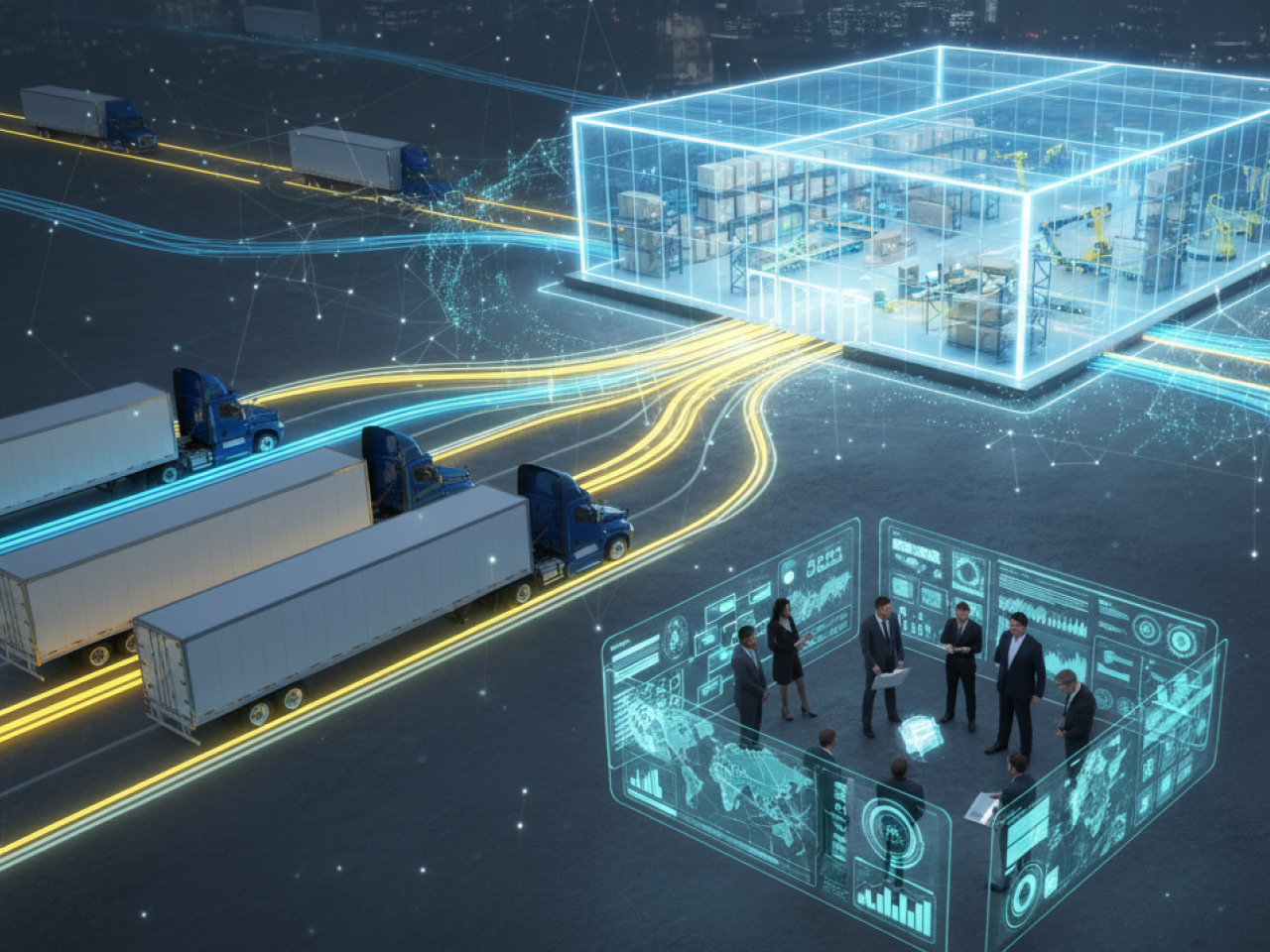

AI-Powered Supply Chain Control for High-Tech Manufacturing

With 18-24 month order cycles and shipments flowing through multiple freight forwarders globally, hundreds of team members spend their days on manual tracking. FourKites offers instant responsiveness on in-transit freight 24/7 with AI agents, reducing the need to work with offshore teams.

Supply Chain Maturity in High-Tech Manufacturing

Current State: Reactive Mode |

Future State: Predictive Mode |

|---|---|

|

Shipment Blindness Across Forwarders Freight forwarders operate in their own silos. Teams lack unified visibility across your multi-forwarder network, creating coordination chaos. Potential business impacts: Lost Revenue from Production Delays, Expedited Freight Costs, Customer Penalty Clauses, Inventory Carrying Costs, Detention/Demurrage Costs |

Carrier-Agnostic Intelligence Unlike freight forwarders who compete with your logistics partners, FourKites provides truly agnostic visibility across the entire network—petabytes of data inform predictions. |

|

Manual Monitoring at Scale Teams manually track thousands of shipments 24/7. Every inquiry requires phone calls, emails, or portal checks across dozens of carriers and forwarders. Potential business impacts: Labor Overhead, Headcount Growth, Human Error Cost |

AI Agents Replace Manual Tasks Digital workers manage the day-to-day tasks, like monitoring shipments 24/7, reaching out to carriers via phone, email, SMS, and WhatsApp when exceptions occur. Scale infinitely without adding headcount. |

|

Reactive Exception Management Engineers escalate distressed shipments to control tower teams who then contact carriers for updates. By the time you learn about delays, you've already lost days of reaction time. Potential business impacts: Production Line Downtime, Expedited Costs, Missed Customer SLA’s, OTIF Penalties, Emergency Manufacturing, Customer Churn Risk, Detention/Dwell Costs |

Predictive Exception Management Dynamic ETAs flag delays 7+ days before arrival dates, giving teams time to reroute, expedite, or adjust production schedules proactively. |

|

Supplier Visibility Gap Raw materials and components from hundreds of suppliers lack real-time tracking. Production delays start before shipments even leave the factory. Potential business impacts: Production Line Downtime, Increased Inventory Hold Time, Higher Working Capital, Higher Procurement Costs |

Order-to-Delivery Visibility Connect ERP systems to transportation networks. Track from PO creation through manufacturing, loading, transit, and final delivery—all in one platform, giving you weeks of warning for potential delays. |

|

Customer Communication Lag Sales teams can't provide accurate delivery updates. Customers waiting on critical installations receive generic transit windows instead of dynamic ETAs. Potential business impacts: Labor Overhead, NPS, Top Line Impact, Premium Support Costs |

Automated Customer Updates Provide customers with real-time tracking and proactive delay notifications to eliminate the constant 'where is my order?' inquiries. |

|

Fragmented Technology Stack Separate systems for ocean, air, ground, and parcel create data silos. No single source of truth exists across your global logistics network. Potential business impacts: IT Costs, Data Reconciliation Costs, Decision Latency, Audit/Compliance Risks |

Unified Platform One system integrates ocean, air, LTL, FTL, parcel, and rail across all geographies. Teams see the complete picture, partners maintain their autonomy. |

FourKites Implementation: Minimal Disruption, Maximum Impact

We understand teams are focused on scaling production, launching next-generation products, and meeting customer commitments. Our implementation approach is designed for minimal disruption to the operation.

FourKites project management guides the entire process:

Integration Across Your Freight Forwarder Network

- Works with existing partners—Works with freight forwarders without forcing changes to their processes

- Connects to software systems—ERP, TMS, or existing coordination workflows

- Respects existing relationships—suppliers and carriers continue operating as they do today, FourKites adapts to their needs – not the other way around

- No technology mandates—flexible integration adapts to each partner’s capabilities, ranging from simple emails to APIs

Leverage An Existing Network

Thousands of suppliers and freight forwarders already use FourKites (1,600+ brands in network). When partners are existing customers, you gain visibility into their shipments immediately—no setup delays, no partner coordination required.

Our team identifies network overlap and closes gaps across the rest of your ecosystem.

How Industry Leaders Transform Operations

From Manual Coordination to Strategic Focus

Companies managing complex, high-value supply chains face similar challenges. Here's how FourKites customers transformed their operations:

“We're seeing a huge reduction in email volume related to tracking. I was able to free up 75% of one person’s role so they could focus on other critical projects and strategic initiatives. … FourKites has also improved carrier scorecarding. That used to be a very manual, time consuming process. Now we can not only create reports faster, but by having extra milestones from FourKites’ data, we're able to zoom in on the true root causes of shipment delays.”

"AI handles routine tasks while our teams focus on strategic activities that require experience and business understanding."

“There’s data democratization, where you can see stuff that is happening much faster on a daily basis. There’s much more transparency on issues we are facing, and the team is going in eyes wide open and trying to find solutions as quickly as we can.”

“In the past, our market personnel had to wait for a notification that the material had arrived, then they would schedule a pickup potentially a day or two out. Now, they know exactly when to arrive which reduces unnecessary wait time. In the end, this has helped not only improve visibility within our supply chain, but it's actually reduced the amount of time it takes for us to get material into the hands of our end users.”

Why FourKites for High-Tech Manufacturing

Free Trapped Capital

Digital twins track in-transit inventory to optimize working capital.

Eliminate Safety Stock

Full supplier visibility means you stock what you need, not extra.

Track at the Package Level

Using IoT devices across all modes globally.

Connect Fragmented Systems

Unite disparate data into one intelligent command center.

Slash Manual Updates

AI handles carrier, vendor and customer communications, cutting busywork by up to 80%.

Reduce Service Costs

Automated responses handle customer inquiries without human touch.

Ready to Transform Your Supply Chain?

Your production schedules are critical. Your customers are waiting. Your components can't afford delays.

Let's discuss how FourKites can eliminate operational barriers and scale with you.

FourKites Intelligent Control Tower® tracks 3+ million shipments daily across ocean, air, ground, rail, and parcel—powered by AI agents that turn data into decisions.