The Ultimate Bond:

Sealing the Gaps in Your Supply Chain

28,000 SKUs. 30,000 raw materials. One supply chain platform that bonds it all together.

Current State: When Complexity Doesn’t Adhere to Plan

HB Fuller isn’t just a chemical company—you’re “more of a formulator,” as Celeste Mastin puts it.

With 28,000 SKUs (half custom-tailored), 30,000+ specialty raw materials, and 5,000 new formulations annually, this isn’t ordinary complexity.

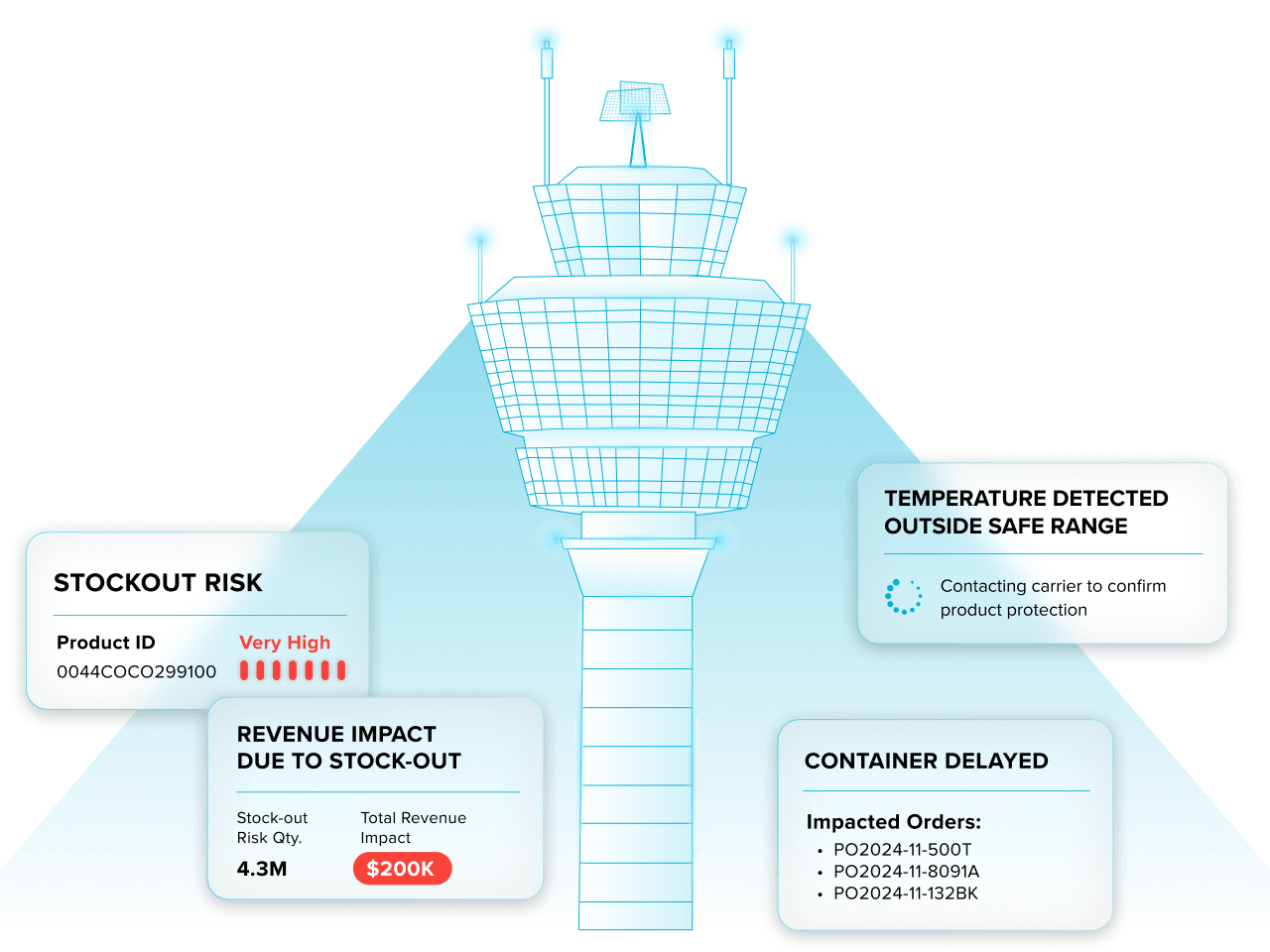

The FourKites Intelligent Control Tower™ fuses real-time supply chain insights with AI-driven execution that sticks with your products from formulation to delivery, enhancing customer experience and accelerating strategic growth.

HB Fuller’s Future State: Supply Chain Transformation with the Intelligent Control Tower™

With the FourKites Intelligent Control Tower™, HB Fuller will experience:

- Automated exception management and visibility across all 28,000 SKUs, freeing your team to focus on strategic initiatives

- AI-powered predictive analytics that identify raw material shortages weeks before impact

- Enhanced customer satisfaction through precise delivery ETAs and proactive communication

- Seamless facility consolidation with significantly reduced disruption risk

- Accelerated digital transformation through enhanced supply chain intelligence

- Smooth integration of 5,000 new SKUs annually with minimal disruption

Why settle for simple tracking? Take advantage of intelligent tools that automate high-value actions the second they’re detected.

Proven Results: How Henkel Adhesives Solved Similar Challenges

CHALLENGE

Like HB Fuller, Henkel’s Adhesive Technologies division manages a complex portfolio of adhesives, sealants, and functional coatings. Just as you face challenges with 28,000 SKUs and 30,000+ raw materials, Henkel struggled with tracking their products across numerous logistics service providers, which impacted customer satisfaction and operational efficiency.

SOLUTION

Henkel implemented FourKites’ platform to improve end-to-end supply chain intelligence, with particular focus on tracking over-the-road shipments from warehouse pickup to customer delivery—exactly the kind of visibility needed for your specialized chemical formulations and custom-tailored products.

RESULTS

Customer experience transformation

Henkel drastically reduced response time to status inquiries and enabled customers to proactively track shipments, critical for HB Fuller’s 30,000+ customers

Time and cost savings

Eliminated the burden of manual tracking, freeing customer service teams to focus on higher-value activities—directly addressing your need for 40% more operational capacity

Supplier accountability

Gained the insights needed to proactively address service issues and reward providers that meet or exceed agreements, essential for managing your 30,000+ raw materials

Dispute resolution

Reduced late fees through accurate delivery data that enables quick verification or disputes of late claims, supporting your path to 20%+ EBITDA margin

“Once we started our rollout with FourKites and more people saw what it could do and the value it can deliver, there was a strong demand for FourKites access from across our organization.”

— Istvan Lencz, Head of Logistics, Henkel Adhesives Division

Additional Success: How 3M’s Supply Chain Stuck Together in Crisis

CHALLENGE

When 3M faced unprecedented demand for respirators in 2020, they encountered challenges similar to what HB Fuller faces during its facility consolidation: complex manufacturing processes under pressure, supply disruptions, and the need to maintain service levels during major operational changes.

SOLUTION

3M turned to FourKites for end-to-end visibility as a critical component of their supply chain strategy. The platform unified manufacturing, supply chain, and customer operations under one system—exactly what HB Fuller needs today. With 28,000 SKUs and 5,000 new formulations annually, your team requires this same unified view to maintain the speed of innovation that keeps you ahead of competitors.

RESULTS

Data democratization

“There’s data democratization, where we can see stuff that is happening much faster on a daily basis. There’s much more transparency on issues that we are facing, and the team is going in eyes wide open and trying to find solutions as quickly as we can.” — Monish Patolawala, former SVP and CFO, 3M

Rapid implementation

FourKites sealed the deal with 3M’s parcel tracking in just “a couple days to a week”—essential timing for your ongoing facility consolidation

Single source of truth

All stakeholders—from production to customer service—formed a cohesive bond with one unified view of real-time supply chain data—critical for coordinating your 28,000 SKUs

Cross-functional impact

3M permanently bonded FourKites data across departments, dissolving silos that previously hindered collaboration—supporting your digital transformation initiatives

A Deep Dive Into Technology That Bonds Your Supply Chain Challenges

FourKites Intelligent Control Tower: Tailored for HB Fuller’s Complexity

World’s Largest Supply Chain Network

3.2+ million shipments tracked daily across 200+ countries—critical for a global adhesives leader managing specialty chemical shipments from suppliers across continents. When raw material shortages threaten your custom formulations, you need this level of global intelligence and predictive insights.

Digital Twins for Your 28,000 SKUs

Virtual replicas of your complex product portfolio, creating a single source of truth across your operation. Instead of chasing data in spreadsheets and emails, your team instantly sees the status and risk level of every order—essential as you consolidate from 82 to 55 facilities without disrupting customer deliveries.

AI-Powered Digital Workforce for Your Specific Challenges

Sam | Raw Materials Manager

Transforms your supplier emails and documents into instant shipment intelligence across all 30,000+ specialty ingredients. Sam coordinates with your suppliers to track orders, manage exceptions, and ensure on-time delivery of critical raw materials. With 87% of your materials being specialty chemicals, Sam’s ability to predict shortages weeks before they impact production is critical to preventing costly formulation disruptions.

Tracy | Customer Experience Coordinator

Manages carrier communications and proactively investigates exceptions for your 30,000+ customers. Tracy provides real-time order updates and handles routine questions, reducing customer service inquiries by up to 60%. As you introduce 5,000 new SKUs annually, Tracy ensures your customer service team isn’t overwhelmed by routine status inquiries, freeing them to support your innovation pipeline.

The Impact for HB Fuller

Our technology delivers proven results for adhesives industry leaders, and based on verified customer metrics, here’s what HB Fuller can expect:

70-80%

Reduction in Time Spent on Manual Tasks

40-60%

Less Time Spent on Coordination

15-20%

Reduction in Expedited Shipping Costs

10-15%

Decrease in Operational Costs

5-10%

Improvement in On-Time Delivery Performance

Why Global Leaders Choose FourKites

"Co-innovating and implementing the digital worker, Tracy, has helped Unilever teams in the U.S. make our supply chain management more efficient. Within four weeks, we observed notable improvements to exception management and tracking quality."

Ready to Create an Unbreakable Bond?

Your supply chain should be as reliable as your adhesives.